In the world of mechanical systems, flexibility and reliability are key to ensuring smooth operations, minimal downtime, and optimal efficiency. Whether it’s in conveyor belts, automation systems, or other machinery, selecting the right components is crucial for achieving these goals. Two such essential components that significantly contribute to system flexibility and reliability are the MXL timing pulley and roller chain couplers.

At Voodoo Sprockets, we understand the vital role that these parts play in ensuring your systems perform at their best. In this blog, we’ll explore how the MXL timing pulley and roller chain couplers work together to improve system flexibility and reliability, and why you should consider choosing Voodoo Sprockets for your power transmission needs.

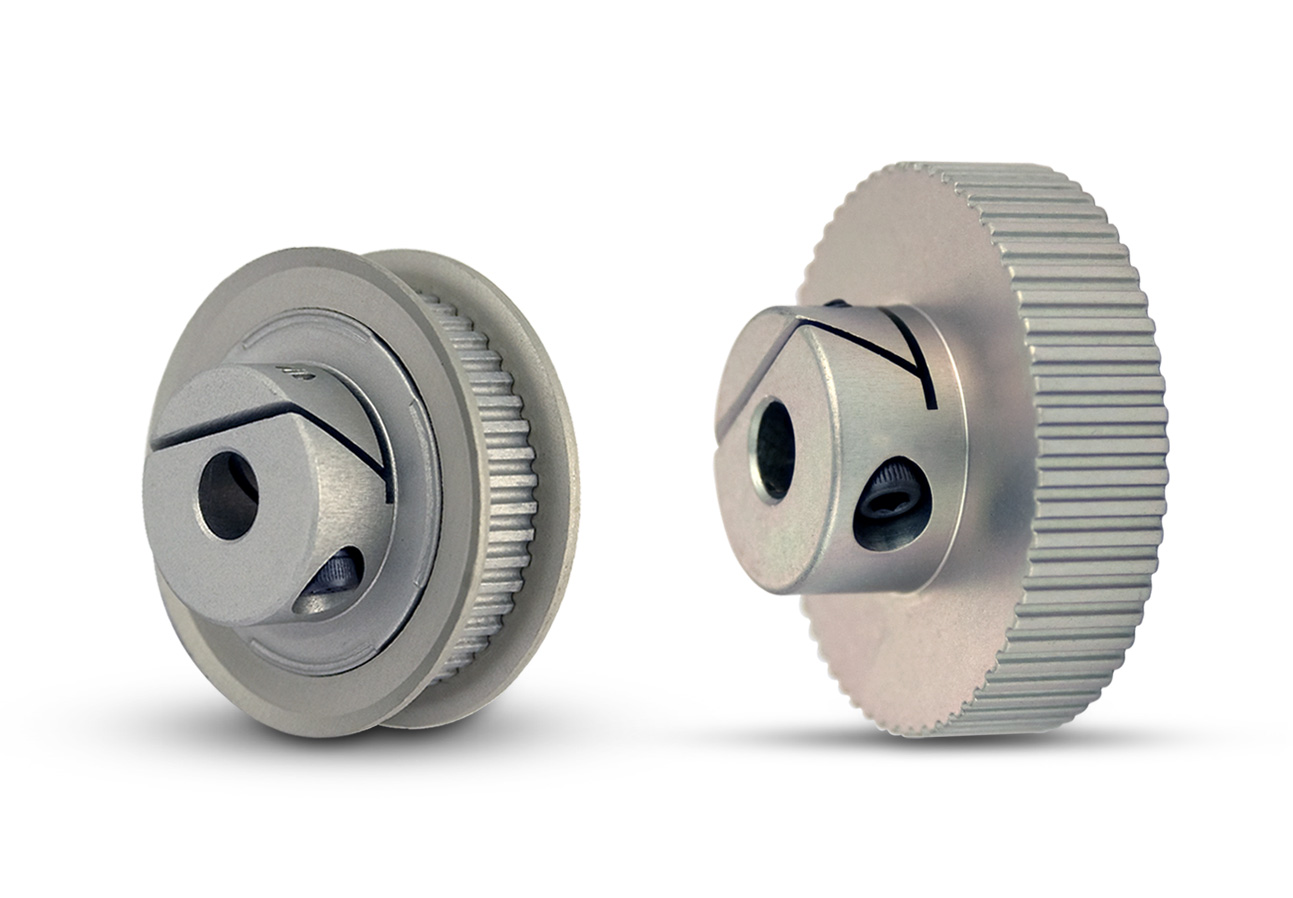

MXL Timing Pulley: Precision and Flexibility in Power Transmission

The MXL timing pulley is a crucial component for power transmission, especially when precise, synchronized motion is needed. Used in various mechanical systems, MXL timing pulleys ensure accurate movement and force transmission by engaging with timing belts that have teeth. These teeth match precisely with the grooves of the pulley, creating a system that eliminates slippage, reduces wear, and delivers consistent performance over time.

Key Features of MXL Timing Pulley

- Precise Synchronization

One of the standout features of the MXL timing pulley is its ability to provide precise synchronization between shafts in mechanical systems. The teeth on the pulley mesh perfectly with the teeth of the timing belt, allowing for controlled, smooth, and consistent rotation. This prevents the common issues associated with traditional belt systems, such as slippage or loss of torque. - Enhanced Durability

MXL timing pulleys are typically made from durable materials such as aluminum, steel, or plastic, offering excellent wear resistance. This durability ensures that the pulley maintains its performance over time, even in high-stress environments. - Compact Design

The MXL timing pulley is designed to be compact, making it an ideal choice for applications where space is limited. Its smaller size allows for efficient power transmission without taking up too much room in the system. - High Efficiency

The precise tooth profile of the MXL timing pulley allows for high-efficiency power transfer. Unlike other systems that rely on friction, the tooth engagement in timing pulleys minimizes energy loss and provides more accurate and reliable performance.

How the MXL Timing Pulley Enhances Flexibility

The MXL timing pulley contributes to system flexibility by offering several important advantages:

- Adjustability: MXL timing pulleys allow for easy adjustment in tension and alignment, ensuring that even as systems change or experience wear, they can be adapted without major downtime or adjustments.

- Variety of Sizes: The versatility of MXL timing pulleys in terms of size, number of teeth, and pitch allows them to be used in a wide range of applications, from small machinery to large industrial systems. This flexibility in design means that they can fit into nearly any system, allowing for easy integration into existing setups.

- Smooth Operation: The precision of the MXL timing pulley helps in delivering smooth, continuous power transmission. The elimination of slippage means that the system can handle variations in load or speed without sacrificing performance.

When paired with other high-quality components, such as roller chain couplers, the MXL timing pulley is even more effective in improving system flexibility.

Roller Chain Couplers: Strength, Flexibility, and Reliability

While the MXL timing pulley is responsible for ensuring precise, synchronized movement, roller chain couplers are designed to connect shafts and transfer torque in a reliable, flexible manner. These couplers are vital in systems where two shafts need to be connected but may experience misalignment or slight movement due to operational conditions.

How Roller Chain Couplers Work

Roller chain couplers consist of two sprockets connected by a roller chain. The sprockets are typically designed to fit together and engage with each other via the roller chain, transmitting rotational motion between shafts. This coupling method is ideal for systems where torque needs to be transmitted over longer distances or in applications where space is constrained.

Key Features of Roller Chain Couplers

- Flexibility in Alignment

One of the primary benefits of roller chain couplers is their ability to accommodate slight misalignments between shafts. Whether it’s radial, angular, or axial misalignment, the roller chain provides a degree of flexibility, allowing for smoother operation and reducing the stress on the system. - Torque Transmission

Roller chain couplers can handle high-torque applications efficiently. They ensure that the full torque generated by the driving shaft is transmitted to the driven shaft, preventing power loss and ensuring the system runs efficiently. - Durability

Built from high-strength materials, roller chain couplers are designed to last. With proper maintenance, they can perform reliably over a long service life, even in harsh industrial environments. - Energy Efficiency

Unlike traditional couplers, roller chain couplers can help reduce energy loss during torque transmission. The direct connection between sprockets and chains ensures that power is efficiently transferred with minimal friction or slippage.

How Roller Chain Couplers Contribute to System Reliability

Roller chain couplers are essential for improving system reliability in the following ways:

- Reduced Wear and Tear: The flexibility of roller chain couplers ensures that the components in the system experience less wear and tear. This is especially important in systems where shafts may shift or experience minor misalignments due to operational factors.

- Efficient Torque Transmission: Roller chain couplers provide a direct connection between shafts, ensuring that torque is efficiently transmitted without the losses seen in traditional couplings. This results in a more reliable system with less need for frequent repairs.

- Shock Absorption: In applications where sudden shocks or vibrations can occur, roller chain couplers help absorb these forces, preventing damage to the rest of the system. This shock-absorbing ability improves system longevity and reduces downtime.

How MXL Timing Pulley and Roller Chain Couplers Work Together for System Flexibility and Reliability

When combined, the MXL timing pulley and roller chain couplers create a seamless and highly reliable system capable of handling precise and flexible power transmission. The cooperation between these two components brings several key benefits:

1. Synergistic Power Transmission

By using the MXL timing pulley in conjunction with roller chain couplers, you ensure that power is transmitted with both precision and flexibility. While the timing pulley provides accurate, synchronized movement with no slippage, the roller chain coupler ensures that torque is transferred efficiently and accommodates any misalignment or movement between the shafts.

2. Flexibility in Misalignment

While MXL timing pulleys excel at maintaining precise timing and minimizing slippage, roller chain couplers offer the flexibility needed to account for any misalignments in the system. This flexibility prevents excessive wear and damage to the components, allowing the system to operate smoothly even under varying conditions.

3. Enhanced System Longevity

Both MXL timing pulleys and roller chain couplers are designed to minimize wear and tear, which means that when they work together, the overall system is more durable. The reduced friction and shock absorption properties of roller chain couplers, combined with the precise, slip-free operation of the MXL timing pulley, extend the lifespan of the entire system.

4. Improved Efficiency

Combining the best features of both components results in a highly efficient system. The MXL timing pulley ensures accurate and efficient power transfer, while roller chain couplers enhance torque transmission and offer flexibility, reducing energy loss and increasing operational efficiency.

Why Choose Voodoo Sprockets for Your Power Transmission Components?

At Voodoo Sprockets, we specialize in providing high-quality, durable power transmission components designed to enhance system flexibility and reliability. Our MXL timing pulleys and roller chain couplers are engineered to deliver top-tier performance, making them ideal for both simple and complex mechanical systems.

Benefits of Choosing Voodoo Sprockets:

- High-Quality Materials: Our components are made from premium materials to ensure durability and longevity, even in demanding applications.

- Precision Engineering: With a focus on precision, Voodoo Sprockets ensures that each part is manufactured to meet stringent quality standards, ensuring accurate performance.

- Customization: We offer tailored solutions to meet your specific needs, helping you optimize system flexibility and performance.

- Expert Support: Our team of experts is always available to provide guidance and support, helping you select the right components for your system.

The combination of MXL timing pulleys and roller chain couplers is a powerful solution for enhancing the flexibility and reliability of mechanical systems. By offering precision, durability, and efficiency, these components work in tandem to ensure smooth, reliable, and efficient power transmission. With Voodoo Sprockets providing high-quality components, you can trust that your system will operate at its best, reducing downtime and increasing productivity.

Whether you’re upgrading your current system or building a new one, the right components make all the difference. Choose Voodoo Sprockets for all your power transmission needs, and experience the difference in performance, flexibility, and reliability.