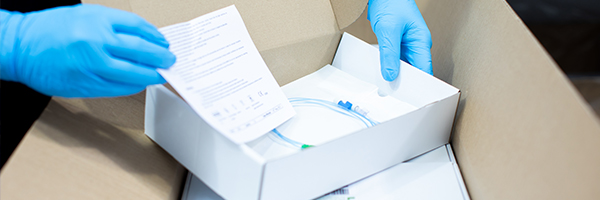

Ensuring that medical devices are properly packaged is crucial to maintaining their sterility, safety, and functionality throughout their lifecycle. Meeting FDA and ISO standards not only protects patients but also strengthens product reliability and trust. This guide outlines each step to achieve compliant and effective packaging for medical devices.

1. Understand Regulatory Requirements

The first step in packaging medical devices is to understand the governing regulations clearly. The U.S. Food and Drug Administration (FDA) enforces rules under 21 CFR Part 820, which focus on quality systems for manufacturing. Similarly, ISO 11607 defines packaging requirements for terminally sterilized devices.

Together, these standards ensure the packaging maintains sterility and physical integrity until the device is ready for use. To start strong, manufacturers should:

- Identify the classification of their devices.

- Understand the sterilization methods involved (EtO, gamma, or steam).

- Determine documentation and labeling requirements based on device risk class.

Each of these considerations influences material selection, validation processes, and recordkeeping.

2. Build a Reliable Packaging System

Once the compliance framework is clear, focus on creating a packaging system that ensures protection, usability, and compliance. A practical design prevents damage, contamination, or exposure to moisture and light during handling and storage.

Here are the key aspects to consider when designing the system:

- Material Selection: Choose sterile, durable, and biocompatible barrier materials compatible with sterilization methods.

- Packaging Configuration: Create a layout that supports aseptic presentation and ease of handling.

- Sustainability Considerations: Where possible, opt for recyclable materials without compromising safety or compliance.

These design decisions directly affect the product’s performance and compliance readiness.

3. Conduct Packaging Validation

Before market release, validation ensures that the medical device system’s packaging performs consistently under real-world conditions. Validation confirms the package’s ability to maintain integrity throughout its shelf life.

Manufacturers should perform tests that replicate shipping, handling, and storage conditions, including:

- Accelerated Ageing Tests: Estimate the product’s shelf life.

- Transit Simulations: Assess resistance to shock, vibration, and compression.

- Environmental Conditioning: Evaluate performance under varying temperatures and humidity.

Comprehensive validation data, documented as per FDA and ISO standards, proves the packaging meets quality and safety expectations.

4. Implement Process Controls and Documentation

Strong process controls help maintain uniformity during production. Each step, from sealing to labeling, should follow well-defined Standard Operating Procedures (SOPs). Trained operators must adhere to these procedures consistently to minimize variability.

Key documents to maintain include:

- Packaging design specifications

- Validation reports and test results

- Sealing and sterilization parameters

All these records should form part of the Device Master Record (DMR). Accurate documentation ensures smooth audits and demonstrates regulatory compliance.

5. Continuous Monitoring and Improvement

Compliance is an ongoing responsibility. Regular audits, internal reviews, and performance monitoring help detect weaknesses early. Feedback from users or post-market surveillance can reveal areas for improvement in packaging materials or methods.

Adopting new technologies such as automated seal testing and real-time environmental tracking can further enhance consistency and reliability. Continuous improvement keeps packaging aligned with evolving standards and market expectations.

Conclusion

Achieving FDA and ISO compliance for packaging medical devices requires a systematic approach, understanding regulations, designing protective systems, validating performance, and maintaining strong documentation. With regular monitoring and process improvement, manufacturers can ensure patient safety, uphold product quality, and remain compliant across global markets.