PP woven bags play an essential role in the packaging industry, offering a durable, versatile, and cost-effective solution for a variety of applications. Constructed from polypropylene, these bags are especially known for their strength and resistance to wear and tear, making them ideal for transporting and storing bulk materials. This Pulkit Plastic Products will provide a comprehensive view of PP woven bags, focusing on their characteristics, manufacturing process, applications across diverse industries, and the significance of PP woven bag manufacturers in promoting sustainability and innovation within the packaging sector.

Understanding PP Woven Bags: Composition and Characteristics

PP woven bags are made from polypropylene, a thermoplastic polymer known for its toughness, lightweight nature, and chemical resistance. The key feature that sets these bags apart is their woven structure, which consists of intertwined polypropylene fibers that enhance their tensile strength. The manufacturing process allows for a range of thicknesses, enabling these bags to withstand varying weights while remaining flexible and easy to handle.

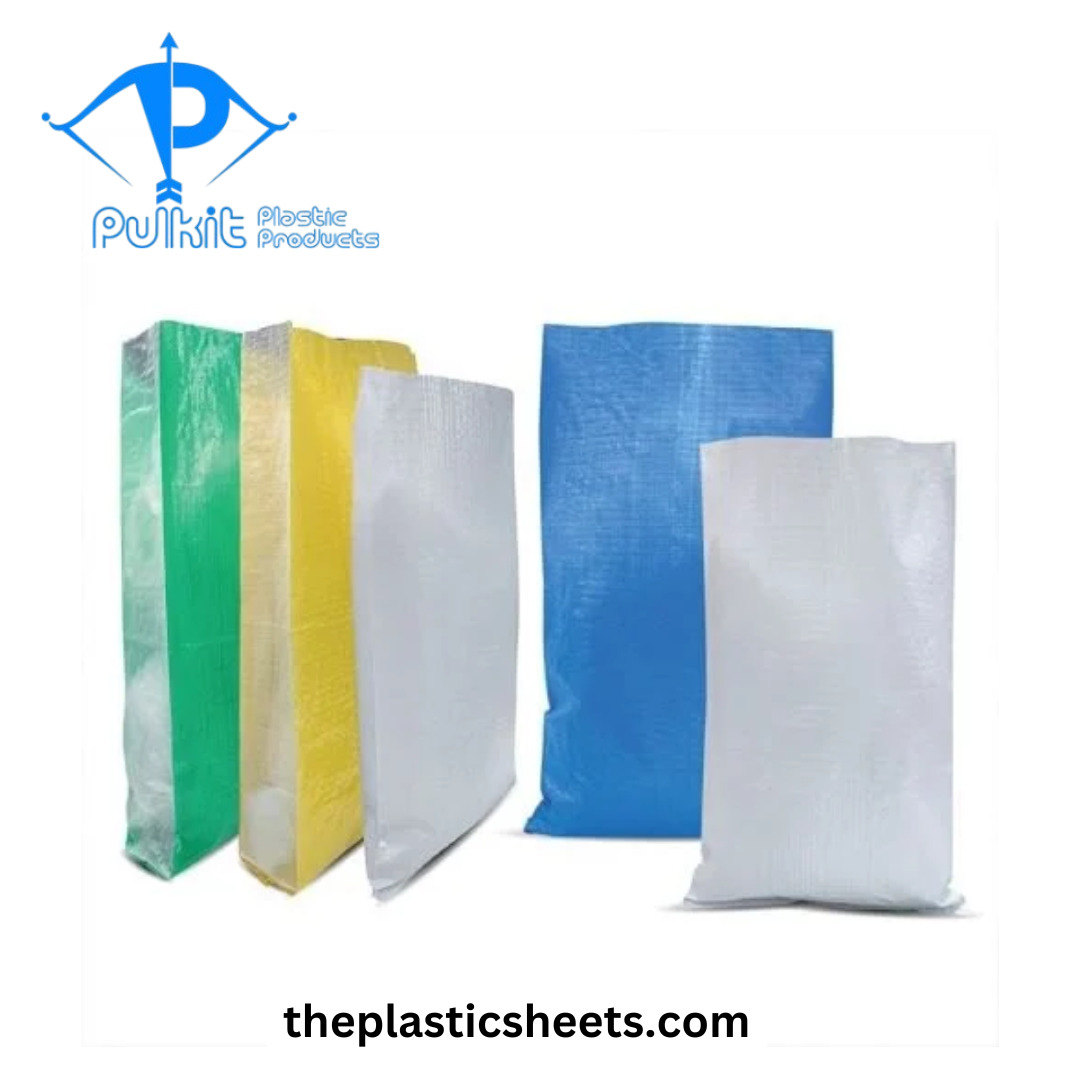

Available in a multitude of colors and designs, PP woven bags images illustrate the bags’ adaptability and aesthetics. Many manufacturers provide customization options, enabling businesses to enhance their branding through printed logos or designs. This customization further extends to the size and shape of the bags, making them suitable for different applications, from carrying agricultural products to packaging construction materials. Overall, the blend of strength, practicality, and visual appeal makes PP woven bags an integral component of modern packaging.

The Manufacturing Process of PP Woven Bags

The production of PP woven bag manufacturers begins with raw polypropylene resin, which is extruded into thin threads or fibers. This extrusion process creates a continuous filament of polypropylene that is then woven into fabric using specialized looms. The resulting fabric can be flat or tubular, depending on the desired bag design. Manufacturers typically produce two types of woven bags: one may have a simple design and be suitable for lighter materials, while others, with reinforced stitching and layers, are designed for heavy-duty applications.

Following the weaving process, the fabric is cut to size and sewn together to form the bags. Quality control is essential during this phase. PP woven bag manufacturers conduct evaluations to ensure the bags meet industry standards for strength and durability. Additional features, such as gussets, handles, and closures, can also be incorporated to enhance functionality and provide a more user-friendly experience.

The entire manufacturing process can be completed quickly and efficiently, allowing manufacturers to produce high volumes of PP woven bags while maintaining consistent quality. The rise of sustainable practices in manufacturing is also influencing the industry, with many manufacturers exploring eco-friendly materials and production techniques in response to consumer demand for greener packaging solutions.

Applications of PP Woven Bags Across Industries

The versatility of PP woven bags leads to their widespread use across various sectors. In the agricultural industry, these bags are commonly employed for packaging grains, seeds, fertilizers, and animal feed. Their resistance to moisture and pests helps preserve the quality of products during storage and transport, providing an effective solution for farmers and agricultural businesses.

In the construction sector, PP woven bags are used to package materials such as sand, gravel, cement, and other bulk construction supplies. The robustness of these bags allows for secure and efficient handling on job sites. They can also be used for waste disposal, providing a convenient way to transport debris from site to disposal areas, ultimately contributing to cleaner work environments.

Retail industries utilize PP woven bags as reusable shopping bags, offering a durable alternative to disposable plastic bags. Customers appreciate the strength and reusability of these bags, which aligns with the increasing emphasis on sustainability in consumer practices. As more retailers adopt eco-friendly initiatives, the demand for PP woven bags as a green alternative continues to grow.

Economic Considerations: Understanding PP Woven Bag Prices

When considering the procurement of PP woven bags, understanding the PP woven bag price becomes crucial. Prices can vary significantly based on factors such as bag size, thickness, customization options, and order volume. Bulk orders often result in lower unit costs, making it more economical for businesses that require large quantities for packaging and shipping.

Additionally, fluctuations in the price of raw materials can impact the cost of production and, consequently, the pricing of finished bags. Market dynamics, including supply chain disruptions and changes in industry demand, can also contribute to price variations. However, investing in high-quality PP woven bags is often considered a cost-effective decision in the long run, as their durability reduces the likelihood of damage and the need for frequent replacements.

Sustainability is also playing an increasingly significant role in pricing. As consumers and businesses prioritize eco-friendly products, there is a rising demand for manufacturers that offer sustainable options, including biodegradable and recycled materials. Although these materials may initially command a higher price, the long-term environmental benefits and alignment with consumer values can outweigh the costs.

The Importance of Quality Assurance

Quality assurance is a vital aspect of the PP woven bag manufacturing process. As various industries rely on these bags for critical functions, ensuring their strength, durability, and structural integrity is essential. Reputable PP woven bag manufacturers implement strict quality control measures at every stage of production.

This often includes material testing, where raw polypropylene is assessed for strength and purity. During production, bags are checked for dimensional accuracy and seam strength. Post-production testing involves conducting load tests to ensure that bags perform as expected under real-life conditions. A comprehensive quality assurance program not only enhances customer satisfaction but also builds trust in the manufacturer’s reputation.

Furthermore, compliance with industry standards and certifications also plays a crucial role in gaining customer confidence. Many consumers are increasingly aware of the importance of quality when it comes to packaging solutions, further emphasizing the importance of rigorous quality assurance practices.

Innovations Shaping the Future of PP Woven Bags

As the packaging landscape evolves, innovations in PP woven bags images are shaping their future. One notable trend is the growing emphasis on sustainability within the industry. As consumers become more environmentally conscious, manufacturers are responding by developing biodegradable or recyclable bags that still maintain the robust characteristics of traditional woven bags.

Technological advancements also contribute to the evolution of PP woven bags. Innovative manufacturing processes, such as automation and digital printing, enhance efficiency and allow for better customization options. These advancements enable manufacturers to produce bags more rapidly while ensuring high-quality standards.

Additionally, incorporating smart technology into packaging is becoming a reality. For instance, some manufacturers are exploring the use of QR codes or RFID tags on bags that allow consumers to track the contents or access information about the product. This added interactivity can enhance customer engagement and satisfaction.

The Role of Consumer Awareness and Demand

Consumer awareness greatly influences the direction of the PP woven bag industry. As shoppers grow more discerning about the environmental impact of their choices, many are opting for products that reflect environmentally responsible practices. This shift has encouraged businesses and PP woven bag manufacturers to align their offerings with sustainable values.

In turn, increased demand for eco-friendly alternatives is pushing manufacturers to innovate continually. Companies that proactively invest in sustainable materials and practices are more likely to attract environmentally conscious consumers, thereby improving their market position.

Moreover, consumer education plays a significant role in promoting the benefits of PP woven bags. Informational campaigns led by retailers and organizations can help consumers understand the importance of reusability and recyclability, reinforcing positive behaviors and practices in everyday life.

Conclusion

PP woven bags are a vital aspect of modern packaging, offering durability, versatility, and sustainability across various industries. From agriculture to retail, the applications of these bags continue to expand due to their robust features and customization options. As consumers increasingly prioritize environmental consciousness, the focus on sustainable practices within the industry will drive further innovation.

The efforts of PP Woven Bag price in promoting high-quality products and enhancing sustainability will determine the future landscape of packaging solutions. By aligning with consumer demands and regulatory requirements, these manufacturers can contribute to a more positive environmental impact while meeting market needs. Through continued innovation and a commitment to quality, the PP woven bag industry is well-positioned for growth and success.

Frequently Asked Questions

1. What are PP woven bags primarily used for?

PP woven bags are used for a variety of applications, including packaging agricultural products, construction materials, retail items, and waste disposal. Their strength and durability make them suitable for both light and heavy products.

2. How can I find reliable PP woven bag manufacturers?

To find reliable PP woven bag manufacturers, you can search online directories, attend trade shows, and check industry reviews. It’s important to assess a manufacturer’s reputation, product range, and quality control practices before making a decision.

3. Are PP woven bags recyclable or biodegradable?

Yes, PP woven bags can be recycled, and many manufacturers are exploring biodegradable options. When purchasing bags, inquire about the materials used and any available recycling programs to promote sustainability.

4. What impacts the price of PP woven bags?

The price of PP woven bags can vary based on factors such as size, thickness, customization options, and order volume. Additionally, fluctuations in raw material costs and supply chain dynamics can also influence pricing.