Introduction to PP Woven Bags

PP woven bags have become an indispensable part of the packaging landscape, known for their robust structure and eco-friendly attributes. Made from polypropylene, a thermoplastic polymer, these bags are engineered to stand the test of time and use. With a rising demand across various sectors, including agriculture, retail, construction, and food packaging, PP woven sacks are proving to be a reliable choice for both manufacturers and consumers. As the market expands, understanding the characteristics, benefits, and applications of Pulkit Plastic Products becomes essential for businesses aiming to enhance their packaging strategies.

Characteristics of PP Woven Bags

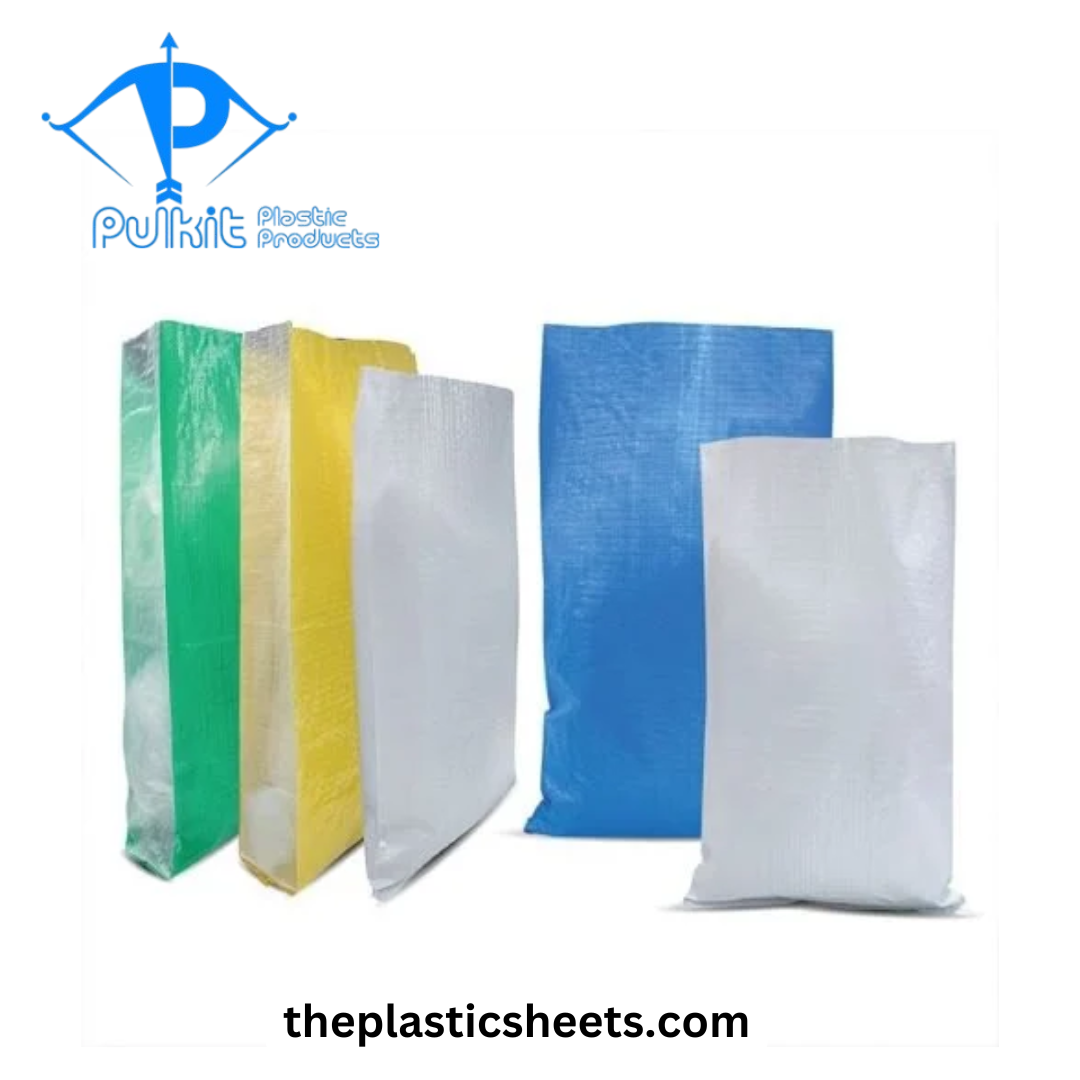

The unique design of PP woven bags sets them apart from traditional packaging solutions. Created by weaving together strands of polypropylene fibers, these bags exhibit impressive tensile strength and durability. Available in various sizes and weight capacities, they can be specifically tailored to meet the product requirements of different industries. Additionally, these bags are resistant to moisture, UV light, and physical abrasion, which allows them to effectively protect contents from environmental and mechanical hazards. Their lightweight nature further contributes to cost-efficiency during transportation, as reduced weight translates into lower shipping costs.

Diverse Applications Across Industries

The versatility of PP woven bags manufacturer makes them suitable for a multitude of applications. In the agricultural sector, they are primarily used for packing grains, seeds, fertilizers, and animal feed, making storage and transportation both efficient and secure. The construction industry employs these bags for holding materials like sand, gravel, and concrete aggregates. Retail sectors have also adopted PP woven bags for eco-friendly shopping, promoting sustainable choices among consumers. Food packaging is another critical sector where these bags serve effectively, especially for bulk items like rice, flour, and sugar in compliance with safety regulations. The adaptability of PP woven bags reflects their standing as a vital tool for businesses aiming to improve packaging efficiency.

Advantages of Using PP Woven Bags

The many benefits of PP woven bags contribute to their widespread adoption. Firstly, their durability and resistance to tears make them long-lasting, providing excellent lifecycle value for businesses. Furthermore, they are reusable and recyclable, aligning with the growing environmental consciousness among consumers. Since the production of PP woven bags does not require significant energy compared to some alternatives, they are viewed as a more sustainable packaging option. Customization capabilities—such as printing options for branding and various sizes—allow businesses to effectively present their products while strengthening their market presence. Ultimately, the advantages of PP woven bags cater to both practical needs and sustainable practices.

Manufacturing Process of PP Woven Bags

Understanding the manufacturing process of PP woven bags sheds light on their quality and reliability. The journey begins with the creation of polypropylene granules, which are melted and extruded to form fibers. These fibers are then woven together using special machines, creating a durable and flexible fabric. The weaving pattern can vary depending on the intended application, influencing the bag’s final strength and stabilization. After weaving, the fabric is cut, stitched, and, if required, printed with logos, labels, or other designs. Quality assurance is conducted at each stage of production, ensuring that the final product meets industry standards and customer specifications. Collaborating with reputable PP woven bags manufacturers guarantees that high-quality materials and craftsmanship are employed throughout the manufacturing process.

Economic Benefits and Cost Efficiency

Companies that choose PP woven sack often find considerable economic advantages. Due to their strength and durability, these bags can carry substantial weights, which reduces the need for multiple packaging solutions. This efficiency significantly lowers manufacturing and logistical costs. Moreover, their lightweight design decreases shipping expenses, making bulk transport more affordable. Given their reusability, businesses can save on recurring packaging costs. As a result, PP woven bags manufacturers play a critical role in reinforcing the financial viability of businesses by providing cost-effective packaging solutions that do not compromise quality or performance.

Environmental Considerations and Sustainability

Environmental sustainability is a pressing concern for many industries, and PP woven bags align well with eco-friendly practices. Made from a recyclable material, these bags can be reused multiple times, reducing overall waste produced by traditional one-time-use plastic bags. Several manufacturers have also started implementing processes that utilize recycled polypropylene, further minimizing environmental impact. The lightweight nature means less energy consumption during transportation, contributing to lower carbon emissions. By adopting PP woven bags, businesses can portray a commitment to sustainable practices, enhancing their brand image and appealing to environmentally conscious consumers.

The Future of PP Woven Bags

The future outlook for PP woven bags remains promising, as more industries recognize their benefits. As global regulations tighten around sustainable practices, the demand for recyclable and eco-friendly packaging is expected to rise. Continuous advancements in manufacturing technology will likely lead to even higher quality and customizable fabric options, enhancing both performance and aesthetics. Additionally, innovations aimed at creating biodegradable versions of PP woven bags signify an exciting future where practicality meets environmental consciousness. By strategically working with a reliable PP woven bags manufacturer, businesses can position themselves at the forefront of this evolving packaging landscape.

Conclusion: The Choice for Modern Packaging Solutions

In conclusion, PP woven bags manufacturers embody an exceptional blend of strength, versatility, and sustainability. Their wide-ranging applications across various industries underscore their significance as an essential packaging solution. With numerous advantages, including cost-effectiveness and environmental friendliness, they are rapidly becoming the preferred choice for businesses eager to enhance their operational efficiencies. Companies looking to invest in this reliable and adaptive packaging option should prioritize forming partnerships with reputable PP woven bags manufacturers to ensure high-quality products tailored to their specific needs.

Frequently Asked Questions (FAQs)

- What are the primary benefits of using PP woven bags?

The main benefits include their durability, resistance to moisture and UV rays, cost-effectiveness, light weight, reusability, and recyclability, making them an ideal choice for various applications. - Can PP woven bags be customized?

Yes, many manufacturers offer customization options for PP woven bags, allowing businesses to choose sizes, colors, and printing for branding purposes. - Are PP woven bags safe for food packaging?

Yes, PP woven sacks are safe for food packaging as long as they comply with health and safety regulations. They are often used for bulk food items like grains, rice, and flour. - How should I clean and maintain PP woven bags?

To prolong the lifespan of PP woven bags, they should be emptied promptly after use and cleaned with a mild detergent and water. Allow them to dry completely before storage to prevent mold or mildew growth.