Jatco shell and tube systems play a important characteristic in numerous industries, ensuring inexperienced warmth switch at the identical time as keeping maximum satisfying operational overall overall performance. These warmth exchangers are widely utilized in programs which includes energy plant life, chemical processing, and HVAC structures because of their durability and performance. Additionally, waste management tanks complement the ones systems thru supplying strong storage and processing solutions for industrial waste, making sure environmental compliance and sustainability. This article explores the importance, applications, and blessings of those critical business additives.

Understanding Jatco Shell and Tube Heat Exchangers

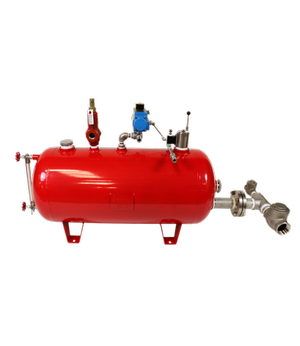

Jatco shell and tube warmth exchangers are designed to facilitate inexperienced heat trade among fluids with out direct contact. Their strong creation allows them to resist excessive strain and temperature versions, making them ideal for demanding business environments. They are widely utilized in oil refineries, power technology, and marine programs because of their capability to deal with huge warmness masses correctly.

Design and Functionality of Shell and Tube Heat Exchangers

The layout of these heat exchangers consists of a shell enclosing a series of tubes via which fluids drift. The warmth trade takes region as one fluid passes through the tubes whilst the other surrounds them, making sure most suitable power switch. This design allows stronger thermal efficiency even as minimizing strength intake, reducing operational costs in commercial settings.

Applications of Shell and Tube Heat Exchangers in Industries

These warmth exchangers are essential in industries which includes chemical manufacturing, food processing, and HVAC systems. Their capability to modify temperatures effectively makes them a preferred choice for approaches that require precise thermal manipulate. They additionally play a key characteristic in maintaining the integrity of sensitive merchandise by means of stopping overheating or thermal degradation.

Advantages of Using Shell and Tube Heat Exchangers

One of the number one advantages of these heat exchangers is their excessive thermal efficiency, which lets in industries to optimize power use. Their durable creation ensures lengthy-term overall performance with minimal renovation, making them a fee-effective solution. Additionally, their modular design permits for smooth customization based on specific business enterprise desires.

The Role of Waste Management Tanks in Industrial Operations

Waste management tanks are vital to industrial tactics, making sure the secure storage and disposal of waste substances. These tanks help industries study environmental policies by means of securely containing risky or non-hazardous waste. Proper waste management complements place of work protection on the identical time as minimizing environmental effect.

Types of Waste Management Tanks for Industrial Use

There are various varieties of waste management tanks, such as underground storage tanks, above-floor containment tanks, and chemical processing tanks. Each kind is designed to deal with extraordinary waste materials, making sure that industries can efficaciously manipulate their byproducts without chance of infection or leaks.

Material Selection for Durable Waste Management Tanks

The materials utilized in building waste manipulate tanks play a essential characteristic in their durability and effectiveness. Common materials consist of chrome steel, fiberglass, and polyethylene, every offering specific benefits in phrases of corrosion resistance, strength, and sturdiness. Choosing the right cloth guarantees handiest overall performance and compliance with safety necessities.

Integration of Shell and Tube Heat Exchangers with Waste Management Tanks

Industries frequently combine warmness exchangers with waste management systems to beautify performance. The warmth recovered from enterprise processes can be used for waste treatment, decreasing strength consumption and enhancing sustainability. This integration lets in corporations to optimize property even as retaining regulatory compliance.

Maintenance and Safety Considerations for Industrial Equipment

Regular protection is essential to make sure the durability and normal overall performance of every heat exchangers and waste control tanks. Inspections, cleaning, and habitual servicing help prevent troubles along side corrosion, leakage, or clogging. Adhering to safety protocols minimizes risks and complements operational performance.

Environmental Benefits of Proper Heat Transfer and Waste Management

Implementing inexperienced heat change and waste manipulate solutions contributes to environmental sustainability. Reducing energy waste and nicely coping with enterprise byproducts allows industries lower their carbon footprint. These structures assist eco-friendly practices through minimizing emissions and optimizing resource use.

Future Trends in Heat Exchange and Waste Management Technologies

Advancements in materials and layout hold to enhance the efficiency of warmth exchangers and waste manage tanks. Innovations which includes clever monitoring systems, electricity restoration solutions, and more suitable corrosion-resistant coatings are shaping the destiny of industrial operations. These trends make a contribution to greater sustainable and cost-effective business strategies.

Conclusion

The integration of Jatco shell and tube warmth exchangers with waste management tanks plays a important function in enhancing industrial performance and sustainability. These structures beautify strength conservation even as ensuring accountable waste handling, making them essential in various industries. As era advances, persisted improvements in warmth exchange and waste manage answers will pressure green commercial operations, making sure prolonged-time period blessings for each agencies and the surroundings.