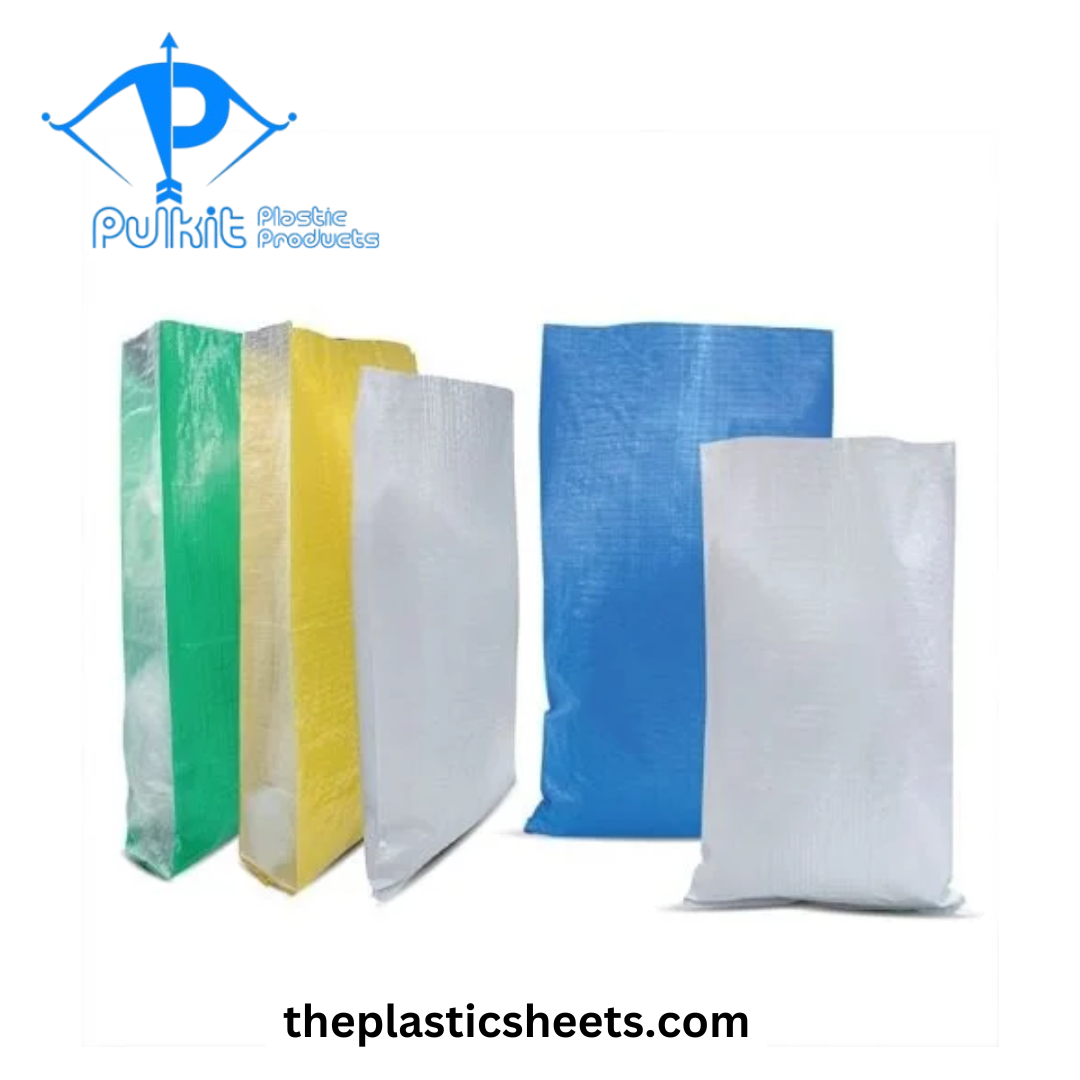

In the realm of packaging and storage solutions, PP woven bags stand out as a remarkably versatile and widely employed option. These bags, constructed from woven strands of polypropylene, offer a robust and cost-effective solution for a vast array of applications, from agricultural products to industrial materials. This Pulkit Plastic Products provides an in-depth examination of PP woven bags, exploring their construction, benefits, applications, and the role of a polypropylene bags manufacturer in meeting the growing demand for this essential packaging material.

Decoding the Anatomy of PP Woven Bags

Understanding the construction of a PP woven bag is crucial to appreciating its strength and durability. The primary component is polypropylene, a thermoplastic polymer renowned for its excellent tensile strength, chemical resistance, and relatively low cost. These properties make polypropylene an ideal choice for packaging materials. During the manufacturing process, polypropylene resin is melted and extruded into thin, strong filaments. These filaments are then woven together on specialized looms to create the fabric for the bags. The weaving pattern contributes significantly to the bags’ strength, allowing them to withstand considerable weight and stress. Depending on the application, the fabric may be laminated with a thin layer of polyethylene or other materials to enhance its moisture resistance, provide printability, or improve overall barrier properties.

The design of PP woven bags is adaptable, allowing for customization to meet specific needs. The bags can be produced in various sizes, with different closures like heat-sealed tops, open tops with stitched hems, or valve closures for efficient filling. Handles can be added for easy carrying, and printing options allow for branding, product information, and other relevant details. The bag’s overall design contributes to its ease of use and its suitability for handling a variety of products.

Unveiling the Advantages of PP Woven Bags

The popularity of Polypropylene woven bags stems from several key advantages that make them a superior choice for packaging and storage. Their exceptional strength and durability allow them to handle significant weights, making them ideal for transporting and storing items like grains, fertilizers, and cement. Their resistance to moisture, chemicals, and tearing provides robust protection for the contents inside.

Furthermore, PP woven bags are cost-effective compared to other packaging options, offering a favorable return on investment for manufacturers. This is particularly important in sectors where large quantities of materials need to be packaged and transported. They are also reusable and recyclable, making them a sustainable option compared to single-use alternatives, contributing to efforts to reduce waste and minimize environmental impact. The inherent ease of printing on the material also adds to the bags’ versatility, allowing for clear branding, product information, and warnings.

A Multitude of Applications: PP Woven Bags in Action

The versatility of PP woven bags allows for a wide range of applications across various industries. The agricultural sector utilizes them for packaging grains, seeds, animal feed, and fertilizers. In the chemical industry, PP woven bags safely transport and store chemicals and resins. They are also essential in the construction sector, where they are used to package cement, sand, and other building materials.

In the food industry, PP woven bags, particularly those with lamination, are employed for packing dry foods like rice, sugar, and flour. They are also used in the transportation of commodities and raw materials across the globe. The adaptability of PP woven bags to various products and industries emphasizes their critical role in supply chains.

The Role of a Polypropylene Bags Manufacturer

The production of PP woven bags is a specialized process, and the expertise of a polypropylene bags manufacturer is critical to ensuring quality and meeting customer demands. Manufacturers must possess advanced weaving machinery, lamination equipment (if applicable), and printing capabilities. They must also have stringent quality control processes in place to ensure the bags’ strength, durability, and dimensional accuracy.

These manufacturers often work closely with clients to understand their specific packaging needs. They can design and manufacture custom-sized bags, incorporate specific closure systems, and provide high-quality printing to meet a client’s requirements. A reputable manufacturer also provides efficient supply chain management, ensuring timely delivery of products. They often offer a range of services including design assistance, material selection, and technical support, making them crucial partners for businesses that rely on PP woven bags.

Addressing Sustainability Concerns

While Polypropylene bags manufacturer offer several advantages, addressing environmental concerns regarding plastic usage is crucial. As mentioned earlier, the bags are reusable and recyclable, but it’s important to note that proper recycling is vital. Many manufacturers are exploring ways to reduce their environmental footprint. They are adopting more efficient manufacturing processes to reduce energy consumption and waste generation. Using recycled polypropylene or exploring biodegradable alternatives can minimize environmental impact. This commitment to sustainability is becoming increasingly important in a market that places high value on responsible business practices.

Future Trends in PP Woven Bag Technology

The industry is continuously evolving, with emerging trends in PP woven bag technology. Manufacturers are developing advanced weaving techniques to create stronger and more lightweight bags. Innovative lamination technologies enhance barrier properties and improve moisture resistance. Advancements in printing allow for more vibrant and detailed graphics, making PP woven bags a valuable tool for branding and marketing. Automation and smart manufacturing practices are also playing a significant role in improving efficiency, reducing costs, and meeting the growing demand for PP woven bags.

Conclusion

The PP woven bags are a workhorse of the packaging industry, offering a blend of strength, versatility, and cost-effectiveness that has made them essential across a vast array of industries. Their production is a highly specialized process, and the expertise of a polypropylene bags manufacturer is vital to meeting specific customer demands. As sustainability becomes increasingly important, exploring recycling and developing alternative materials will be important. Technological advancements will continue to improve the functionality and effectiveness of PP woven bags, solidifying their position as a critical element in global supply chains for the foreseeable future.

Frequently Asked Questions

Are PP woven bags waterproof?

While the woven fabric itself may not be entirely waterproof, PP woven bags can be made moisture-resistant or waterproof by laminating them with polyethylene or other waterproof materials.

How are PP woven bags recycled?

PP woven bags can be recycled, typically through specialized recycling facilities. The bags are cleaned, shredded, and melted down to create new plastic products.

Can PP woven bags be customized with printing?

Yes, PP woven bags can be extensively customized with printing to include logos, product information, branding elements, and warnings. Manufacturers use advanced printing techniques to produce high-quality graphics.

What is the typical lifespan of a PP woven bag?

The lifespan of a PP woven bag depends on its use and care. While they are designed for repeated use and can be quite durable, their lifespan also depends on how they are stored. The specific application, loading, and environmental conditions also play a key role.