Laser cutting has become one of the most valuable tools in modern metal fabrication. As local industries grow, many businesses now rely on Laser Cutting Chilliwack services to achieve cleaner cuts, detailed designs, and consistent results. Whether the goal is to create industrial components, custom art pieces, or durable structural parts, laser cutting helps Chilliwack shops deliver exceptional craftsmanship. Because of its speed, accuracy, and versatility, laser cutting continues to raise the standard of design quality throughout the region.

Unmatched Precision for Clean and Accurate Designs

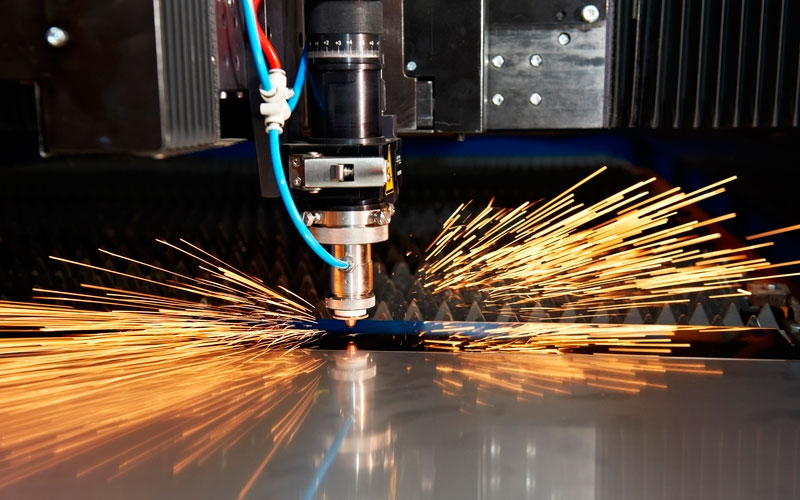

One of the biggest advantages of using Laser Cutting Chilliwack services is the unmatched precision the technology provides. Laser machines use a highly focused beam to cut metal with exceptional accuracy, producing smooth edges and sharp detailing. This precision is nearly impossible to achieve with manual tools or older cutting methods.

Whether customers need delicate patterns, complex shapes, or industrial-grade parts, laser cutting ensures every detail is consistent. Clean edges improve both the appearance and performance of the final product, making this method ideal for high-quality custom work.

Faster Production Without Sacrificing Quality

In today’s fast-moving market, turnaround time matters. Laser cutting significantly speeds up production while maintaining excellent quality. Traditional cutting methods take longer and often require extra finishing steps. In contrast, laser machines cut quickly and produce smooth edges that often need little to no additional polishing.

Because laser cutting works with computer-guided designs, shops can easily repeat the same part multiple times with the exact same dimensions. This consistency helps reduce delays, minimize mistakes, and ensure high-quality results for every project. Faster production also helps Chilliwack businesses meet tight deadlines efficiently.

Better Compatibility With Metal Forming and Bending Work

Laser cutting is often the first step in a larger fabrication process. After cutting, many parts need shaping, forming, or bending. Accurate cuts make these steps smoother. For example, when shops perform Metal Forming Chilliwack services, precise cuts ensure the metal bends correctly without cracking or warping.

Similarly, shops handling Metal Bending Chilliwack projects benefit from laser-cut lines because they help guide where the metal should bend. With accurate cuts and clean edges, bending becomes predictable, resulting in high-quality final products that fit perfectly.

Because laser cutting works so well with forming equipment, fabrication shops save time and reduce errors during the shaping process.

Stronger Welds and Better Structural Quality

Another major advantage is how laser cutting supports clean and accurate welding. When parts come off the laser with smooth edges, welding becomes easier and more professional. Shops offering Metal Welding Chilliwack services rely on precise cuts to ensure strong joints and cleaner weld lines.

Straight edges, accurate measurements, and consistent shapes all help welders achieve better penetration and alignment. This improves the overall strength of the product while also enhancing its appearance. Whether it’s industrial machinery, railings, brackets, or structural components, laser cutting ensures the welding stage delivers high-quality results.

Improved Customization and Creative Design Options

Laser cutting allows Chilliwack shops to achieve creative designs that were previously difficult or impossible to produce. Because lasers can cut complex shapes with small details, customers can request custom designs with confidence.

Shops can produce:

- Artwork and decorative panels

- Custom signage

- Precision brackets and components

- Architectural metal features

- Detailed logos and lettering

- Perforated metal sheets

This flexibility helps businesses, homeowners, and contractors bring their ideas to life. Whether someone wants a custom steel sign or a finely detailed metal panel, laser cutting makes creativity more achievable.

Less Waste and More Efficient Use of Materials

Material waste is one of the biggest concerns in metal fabrication. Laser cutting helps reduce waste by making clean and accurate cuts that use materials efficiently. Because the laser beam is incredibly narrow, shops can place parts closer together on a sheet of metal, saving leftover material.

This not only reduces cost but also supports environmentally responsible practices. Chilliwack shops using laser cutting benefit from higher efficiency, which helps them offer better pricing and faster service.

Smooth Integration With Powder Coating and Finishing

Finishing is an important step in many fabrication projects. When metal surfaces are prepared well, finishing becomes smoother and cleaner. Precise cuts allow coatings to adhere better, improving durability and the final appearance.

For example, shops offering Powder Coating Chilliwack services achieve much cleaner finishes on laser-cut parts because edges are smooth and consistent. Powder coating sticks more evenly to clean surfaces, resulting in a high-quality finish that lasts longer.

Laser cutting also reduces the need for sanding or grinding before finishing, helping shops complete projects faster and with better results.

Reliable for Both Small and Large-Scale Projects

Another benefit of laser cutting is its reliability across different project sizes. Small businesses, contractors, homeowners, and large manufacturers all depend on laser cutting for various tasks. Whether the project involves a single custom bracket or hundreds of repeated parts, laser cutting ensures consistent quality.

This makes the technology useful for:

- Custom home projects

- Manufacturing components

- Industrial machinery parts

- Metal signage

- Commercial construction

Because laser cutting adapts easily to different project needs, it remains one of the most versatile fabrication methods in Chilliwack.

Conclusion: Laser Cutting Raises the Standard of Design Quality

Laser cutting has transformed design and fabrication in Chilliwack shops by improving precision, speeding production, reducing waste, and enhancing creative potential. Its compatibility with Metal Forming Chilliwack, Metal Bending Chilliwack, and Metal Welding Chilliwack makes it an essential part of modern fabrication. When paired with high-quality finishing like Powder Coating Chilliwack, the final results become even more impressive.