In modern manufacturing, optimizing cost, efficiency, and product protection is the key to staying competitive. Across industries—from food and beverage to electronics and pharmaceuticals—producers are increasingly turning to shrink wrap packaging as a reliable and economical solution. This packaging method not only enhances product presentation but also reduces material waste, speeds up operations, and improves logistics efficiency. For manufacturers aiming to streamline production and maximize profits, shrink wrap has become more than a packaging choice—it’s a strategic investment.

The Basics of Shrink Wrap Packaging

Shrink wrap packaging uses a thin, durable polymer film that tightly conforms to a product when heated. The result is a secure, tamper-evident seal that protects goods during transport and storage. The film, typically made from polyolefin or PVC, shrinks uniformly around the product, creating a snug, transparent covering.

This process is typically completed using heat tunnels or sealing machines that ensure consistent application at high speeds. Depending on the requirements, shrink wrap can be used for individual products, multipacks, or even entire pallets. It’s this versatility that makes it one of the most efficient packaging methods for manufacturers across various sectors.

Why Shrink Wrap Packaging Has Become an Industry Standard

Cost Efficiency and Material Savings

One of the primary reasons manufacturers favor shrink wrap is its cost-effectiveness. Compared to rigid packaging options such as boxes or clamshells, shrink film requires significantly less material. It reduces storage space, shipping weight, and overall packaging costs without compromising protection.

Additionally, modern shrink films are thinner yet stronger than earlier versions, meaning manufacturers use less plastic per unit—contributing to both savings and sustainability goals.

Enhanced Product Protection

Shrink wrap creates a tight, sealed barrier that safeguards products from dust, moisture, and environmental contaminants. This is especially critical in industries like food, pharmaceuticals, and electronics, where hygiene and protection are paramount.

The durable seal also prevents tampering and ensures that goods reach consumers in pristine condition. For items prone to leakage or contamination, shrink wrap provides an added layer of security that other materials cannot match.

Space Optimization and Easy Handling

In manufacturing and logistics, space efficiency directly translates into cost savings. Shrink-wrapped items take up less space during storage and shipping, optimizing warehouse space and reducing transportation costs. The smooth, compact packaging also simplifies handling, stacking, and palletizing.

Furthermore, clear shrink film allows products to remain visible, eliminating the need for printed boxes while still showcasing branding through labels or printed sleeves.

Speed and Automation Compatibility

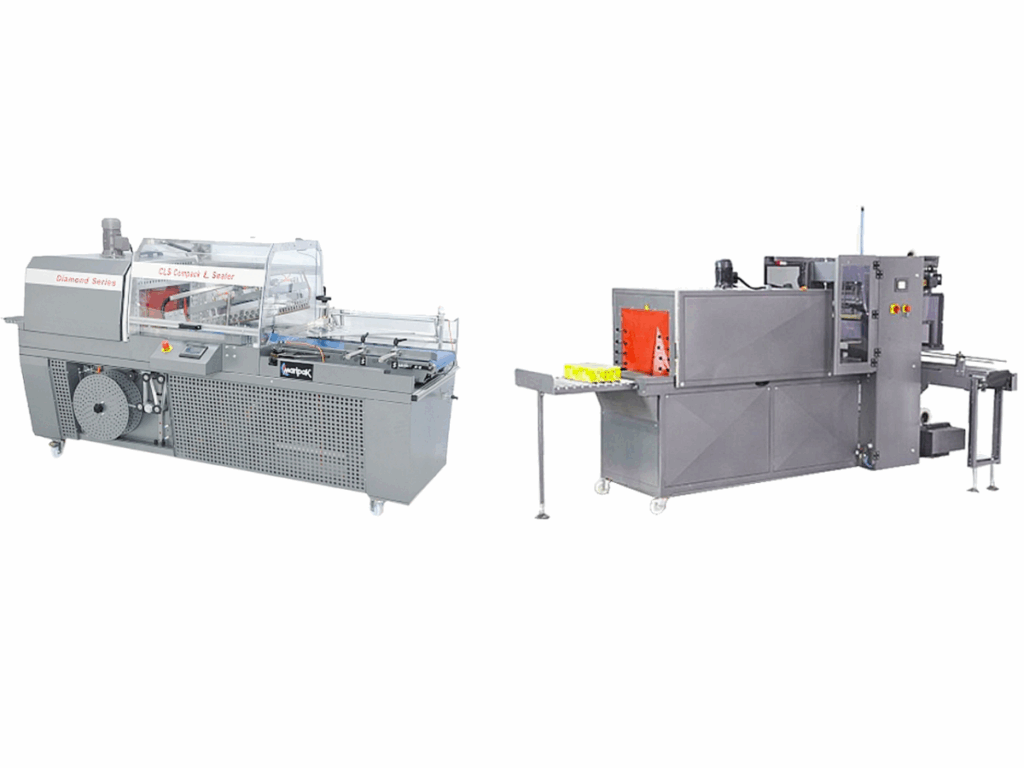

Modern shrink wrap systems are designed for speed and scalability. Automated packaging lines can seal and shrink hundreds of products per minute, drastically improving throughput. With minimal manual intervention, manufacturers can maintain consistent output while reducing labor costs and human error.

The integration of advanced machinery has made shrink wrapping a cornerstone of automated production facilities. Manufacturers can easily adapt machines to different product sizes, shapes, and materials—making it ideal for high-volume, multi-product operations.

Applications Across Industries

Shrink wrap packaging is highly adaptable and is used across numerous manufacturing sectors. In food and beverage, it seals freshness while displaying products attractively. In the pharmaceutical industry, it provides sterile, tamper-proof protection. For electronics, it guards against dust and moisture. In retail and logistics, shrink wrap is commonly used to bundle multipacks or secure pallet loads.

Its flexibility across such a broad range of products has solidified its reputation as a universal packaging solution.

Conclusion

For manufacturers, shrink wrap packaging represents the perfect intersection of functionality, cost savings, and visual appeal. It simplifies production, improves logistics, and provides superior product protection—all while supporting sustainability and reducing overhead costs. To achieve these benefits efficiently, many production lines now incorporate advanced machinery, such as automatic side-sealing machines, which ensure consistent sealing, faster output, and minimal waste.