Graphene has been a revolutionary material since the moment it was discovered, but in 2026, a new form of this wonder material is taking center stage: nitrogen doped graphene. By introducing nitrogen atoms into the graphene structure, researchers and industries are unlocking improved electrical conductivity, higher chemical reactivity, stronger catalytic performance, and more efficient energy storage capabilities.

Why Nitrogen Doping Changes Graphene’s Performance

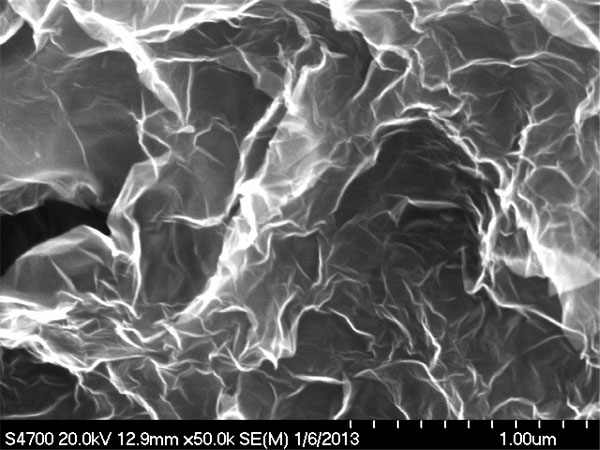

Graphene is already known for its exceptional strength, flexibility, and conductivity. However, doping introduces new properties that take its performance even further. Nitrogen atoms fit naturally into the carbon lattice, and this small change allows graphene to conduct electricity more efficiently while increasing its chemical reactivity.

Additionally, nitrogen creates active sites that improve electron movement, making the material highly valuable in industries looking for advanced solutions. This combination of strength and enhanced conductivity explains why nitrogen doped graphene has become a major topic in research and industrial development.

Better Catalytic Ability for Cleaner Energy Solutions

One of the most promising uses of Nitrogen Doped Graphene is in clean energy applications. The improved catalytic activity makes it an ideal replacement for expensive metals traditionally used in energy systems.

For example, in fuel cells and metal-air batteries, nitrogen doped graphene offers better oxygen reduction performance, which increases efficiency and reduces overall costs. Because of this, industries are exploring this material for next-generation energy devices.

Enhanced Supercapacitor and Battery Performance

Energy storage is another area where nitrogen doped graphene is making a significant impact. Its unique structure increases the surface area available for charge storage, improving both capacity and charge–discharge rates.

As a result, it proves useful in advanced batteries, hybrid capacitors, and large-scale energy storage systems. Manufacturers using CVD Graphene technologies are now able to produce doped graphene with improved purity and structural consistency, allowing businesses to scale up energy storage products more effectively.

Improved Filtration and Environmental Applications

Nitrogen doped graphene also plays an important role in water purification and gas separation. The increased reactivity and adjustable pore structures allow the material to perform with higher accuracy and efficiency.

This makes it suitable for filtration membranes, environmental cleanup systems, and chemical processing equipment. When combined with tools such as Molecular Sieves, doped graphene helps remove impurities at the molecular level, providing cleaner water, purer gases, and better-controlled environments. These innovations represent big steps forward in environmental technology.

Advancements in Sensors and Electronic Devices

The electronics industry is one of the biggest beneficiaries of nitrogen doped graphene. Since doping enhances electrical conductivity and sensitivity, it becomes ideal for use in gas sensors, flexible electronics, and advanced circuit components. Nitrogen sites within the graphene sheet allow the material to detect chemical changes with high sensitivity.

Because of this, industries are integrating doped graphene into wearable electronics, smart devices, and early-detection safety systems. The fast response time and reliability make it a preferred material for next-generation sensors.

Stronger Interaction with Other Materials

One of the advantages of nitrogen doping is the ability to bond more effectively with polymers, metals, and composite materials. This improvement leads to better performance in structural components, coatings, and industrial products.

Industries are using doped graphene to create stronger, lighter, and more durable materials for automotive, aerospace, and construction applications. The improved adhesion also helps manufacturers produce corrosion-resistant coatings and long-lasting protective layers.

Faster Industrial Adoption and Scalable Production

Until recently, doped graphene production was limited to laboratory-scale quantities. However, in 2026, new manufacturing technologies and improved chemical methods are making large-scale production more efficient. Industries can now access doped graphene through trusted suppliers offering consistent quality and reliable delivery.

With scalable methods becoming more accessible, more industries are adopting nitrogen doped graphene than ever before. These advancements help expand its use in electronics, coatings, energy systems, and sustainable technologies.

Support From Global Suppliers and Research Partnerships

As demand grows, the role of global material providers becomes more important. Reliable Graphene Products Suppliers ensure customers receive doped graphene with the right specifications, purity levels, and performance characteristics.

Many suppliers also provide technical support to help researchers and engineers understand how to incorporate the material into their systems. Collaboration between universities, laboratories, and industry leaders is driving rapid innovation.

Conclusion: A Transformative Material With a Promising Future

Nitrogen doped graphene is truly a game-changing material in 2026. Its enhanced conductivity, stronger catalytic activity, improved bonding ability, and exceptional energy storage performance make it ideal for a wide range of industries. From clean energy systems and electronics to filtration and structural composites, this advanced form of graphene opens the door to new breakthroughs.

With reliable support from leading suppliers like ACS Material, industries can explore new possibilities and develop next-generation technologies faster and more effectively. As nitrogen doped graphene continues to evolve, its impact on global innovation will only grow stronger.