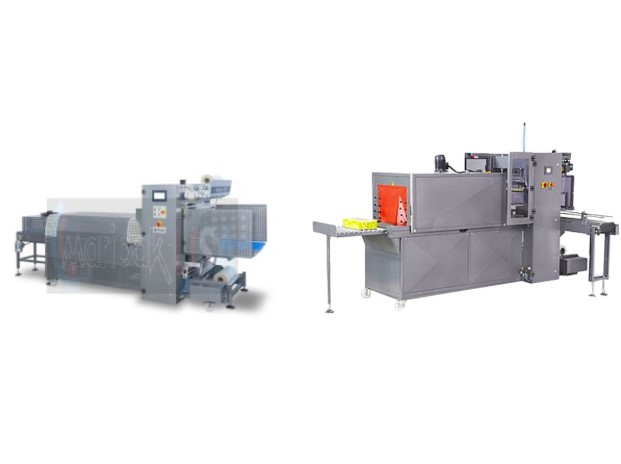

Efficient packaging is essential for businesses handling large volumes of products, whether in manufacturing, logistics, or retail. For companies looking to streamline operations, an automatic side sealing machine offers a practical solution for bulk wrapping. Combining speed, precision, and consistency, this equipment simplifies the packaging process, reduces labor costs, and ensures products are professionally sealed for storage, shipping, or display.

Automatic side sealing machines are designed to handle a wide range of packaging materials and product sizes. By creating tight, uniform seals along the sides of packages, these machines provide a secure and visually appealing finish. When integrated into production lines, they can process hundreds or even thousands of items per hour, making them ideal for businesses that require high-volume packaging without compromising quality.

Advantages of Automatic Side Sealing Machines

High-Speed Packaging for Bulk Orders

One of the most significant benefits of an automatic side sealing machine is its speed. Unlike manual packaging, which is time-consuming and prone to inconsistencies, automatic machines can seal multiple packages continuously with minimal downtime. This high-speed capability makes them perfect for bulk wrapping, where efficiency directly affects productivity and profitability.

For companies dealing with large-scale distribution or e-commerce fulfillment, the ability to process large quantities quickly ensures that deadlines are met and customer satisfaction is maintained.

Consistent and Reliable Seals

Consistency is key in professional packaging. An automatic side sealing machine delivers uniform, strong seals across all packages, reducing the risk of product damage or contamination. Whether using shrink film, polyethylene, or other packaging materials, these machines maintain consistent tension and heat, producing neat edges and secure closures.

This reliability is especially important for businesses distributing products nationally or internationally, where damaged or poorly packaged items can result in returns, complaints, or increased shipping costs.

Versatility for Various Products

Automatic side sealing machines are highly versatile, accommodating different product shapes, sizes, and materials. They can handle individual items, grouped products, or bundles, making them suitable for industries ranging from food and beverages to electronics and consumer goods. This flexibility allows businesses to use a single machine for multiple packaging tasks, reducing the need for additional equipment and optimizing production space.

Labor Savings and Operational Efficiency

By automating the side sealing process, businesses can reduce the need for manual labor. This not only cuts labor costs but also minimizes human error, fatigue, and inconsistencies that can occur during manual packaging. Employees can focus on other value-added tasks, such as quality control, inventory management, or shipping logistics, improving overall operational efficiency.

Enhanced Product Presentation

A neatly sealed package improves product presentation, which is crucial for both retail and e-commerce markets. Automatic side sealing machines create smooth, professional-looking edges that enhance the aesthetic appeal of products. For consumer-facing businesses, visually appealing packaging can improve brand perception, encourage repeat purchases, and support marketing efforts.

Customizable Solutions for Specific Needs

Modern packaging solutions often allow customization to meet specific production requirements. Automatic side sealing machines can be tailored for film type, sealing speed, bundle size, and integration with conveyor systems. This flexibility ensures that businesses can design packaging lines optimized for their unique products, volume, and operational workflow.

Conclusion

An automatic side sealing machine is an ideal choice for businesses that require efficient, reliable, and high-volume packaging solutions. Its speed, versatility, and consistency make it perfect for bulk wrapping, while integration with a shrink bundler enhances product protection and presentation. By reducing labor costs, minimizing errors, and supporting professional-quality packaging, these machines help companies streamline operations, maintain product integrity, and improve overall productivity. For businesses looking to optimize packaging processes, investing in an automatic side sealing machine offers a long-term solution that combines efficiency, precision, and quality.