Oil and Gas Process Simulation Software plays a pivotal role in optimizing operations, enhancing productivity, and ensuring safety in the complex and high-stakes oil and gas industry. These software solutions utilize advanced modeling, simulation, and data analytics to help operators design, analyze, and optimize processes across upstream, midstream, and downstream operations.

This comprehensive guide explores the functionalities, benefits, applications, market trends, and future prospects of oil and gas process simulation software.

What is Oil and Gas Process Simulation Software?

Oil and Gas Process Simulation Software provides a virtual environment to model and simulate operations across the value chain, from exploration and extraction to refining and distribution. These solutions allow engineers and operators to:

- Analyze equipment performance.

- Optimize process efficiency.

- Predict outcomes under varying scenarios.

Key Features

- Thermodynamic and physical property calculations.

- Equipment sizing and optimization.

- Process flow modeling.

- Dynamic and steady-state simulation.

- Integration with real-time data for operational insights.

Importance of Process Simulation in Oil and Gas

The oil and gas industry operates under high stakes, with profitability, safety, and sustainability being paramount. Simulation software helps to:

- Enhance Decision-Making: By providing accurate predictions and detailed process insights.

- Improve Safety: Identifying potential risks and testing emergency scenarios.

- Optimize Operations: Reducing energy consumption and minimizing waste.

- Accelerate Innovation: Supporting the development of new technologies and processes.

Types of Process Simulation

1. Steady-State Simulation

Focuses on processes under constant conditions, commonly used for equipment design and capacity analysis.

2. Dynamic Simulation

Models processes under changing conditions, critical for startup, shutdown, and safety analysis.

3. Flow Assurance Simulation

Ensures the smooth transportation of oil and gas, addressing issues like hydrate formation or pipeline blockages.

4. Reservoir Simulation

Models the behavior of hydrocarbons in reservoirs to optimize extraction techniques.

Applications of Simulation Software in Oil and Gas

1. Upstream Operations

- Reservoir management.

- Drilling optimization.

- Well performance analysis.

2. Midstream Operations

- Pipeline flow assurance.

- Storage and transportation optimization.

- Leak detection and emergency planning.

3. Downstream Operations

- Refinery process optimization.

- Petrochemical production modeling.

- Emission reduction strategies.

4. Environmental Compliance

- Monitoring emissions.

- Designing carbon capture and storage (CCS) systems.

- Evaluating the environmental impact of operations.

Leading Simulation Software in Oil and Gas

1. Aspen HYSYS

Widely used for process design and optimization, offering robust thermodynamic models and equipment sizing tools.

2. Petro-SIM

Focuses on refinery and petrochemical process modeling, providing real-time insights and optimization capabilities.

3. OLGA

Specializes in dynamic multiphase flow simulation, critical for flow assurance in pipelines.

4. Schlumberger’s ECLIPSE

A reservoir simulator for detailed subsurface modeling and production forecasting.

5. CHEMCAD

Flexible simulation software for chemical processes, often used in downstream applications.

Benefits of Process Simulation Software

1. Cost Reduction

Simulation minimizes expensive trial-and-error experiments and identifies cost-saving opportunities.

2. Improved Operational Efficiency

Models help identify inefficiencies and optimize processes to maximize throughput and minimize downtime.

3. Risk Mitigation

Simulating scenarios like equipment failure or process upsets helps plan effective mitigation strategies.

4. Enhanced Safety

Dynamic simulations provide insights into potential hazards, enabling safer plant operations.

5. Regulatory Compliance

Ensures adherence to environmental and safety standards through predictive analysis and reporting.

Challenges in Adopting Simulation Software

1. High Initial Costs

Purchasing and implementing simulation tools require significant investment.

2. Complexity

Learning to use these tools effectively demands specialized training and expertise.

3. Integration Issues

Seamlessly integrating simulation software with existing IT systems can be challenging.

4. Real-Time Adaptation

Adapting simulations to reflect real-time operational changes remains a technical hurdle.

Market Insights

Global Market Size

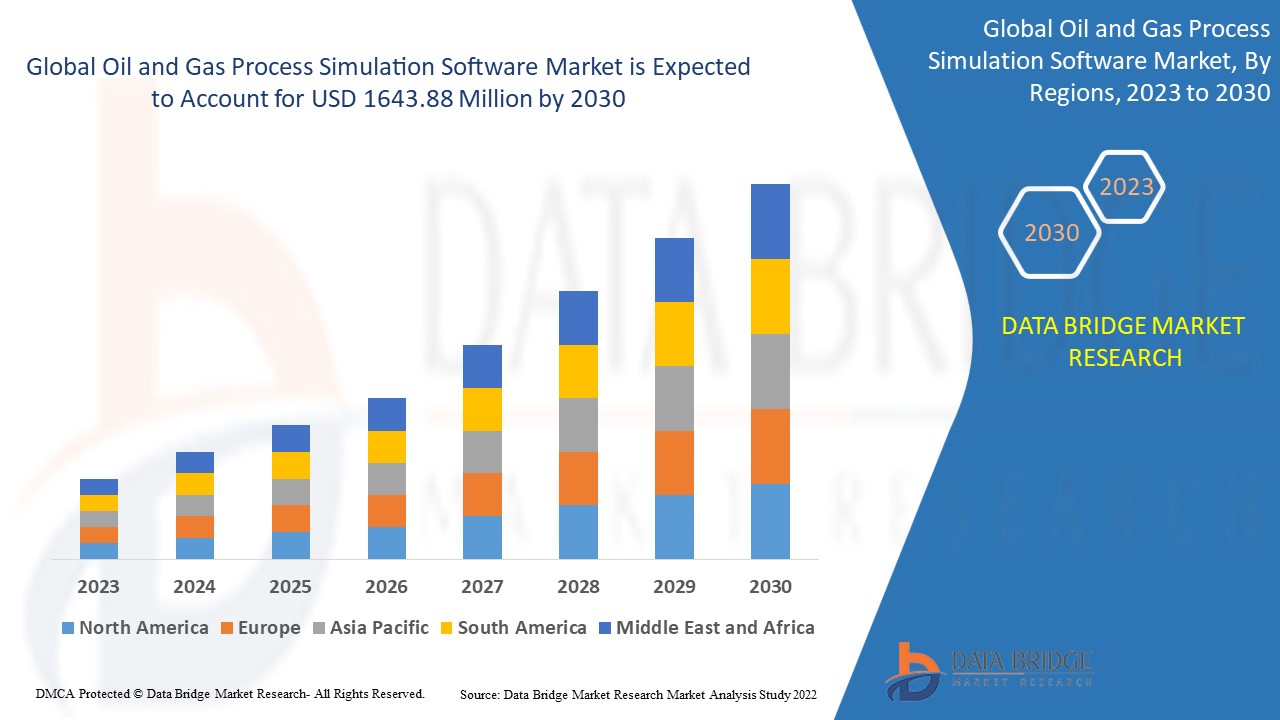

Data Bridge Market Research analyses that the oil and gas process simulation software market was valued at USD 1087.53 million in 2022 and is expected to reach the value of USD 1643.88 million by 2030, at a CAGR of 5.30% during the forecast period.

Key Regions

- North America: Leading market with advanced technological adoption and significant shale gas production.

- Middle East and Africa: Driven by extensive oil reserves and modernization initiatives.

- Asia-Pacific: Rapidly growing market due to increasing energy demand and refinery expansions.

Major Players

- Aspen Technology, Inc.

- Schneider Electric SE

- Honeywell International Inc.

- AVEVA Group plc

- Kongsberg Gruppen

Future Trends in Simulation Software

1. AI and Machine Learning Integration

Advanced algorithms enable smarter simulations, providing predictive insights and adaptive capabilities.

2. Cloud-Based Solutions

Cloud platforms allow for scalable, collaborative simulations with real-time data access.

3. Digital Twins

Creating virtual replicas of assets for continuous monitoring and optimization.

4. Sustainability Focus

Simulations designed to minimize carbon footprints and optimize renewable energy integration.

5. 5G and IoT Connectivity

Enhanced data collection and faster processing for real-time simulation updates.

Sustainability in Oil and Gas

Simulation’s Role in Sustainability

- Optimizing processes to reduce energy consumption.

- Modeling carbon capture systems and renewable energy integrations.

- Reducing flaring and emissions through advanced analytics.

Case Studies

1. Dynamic Simulation for Refinery Expansion

A major refinery used Aspen HYSYS to simulate new processing units, reducing design errors and accelerating project timelines.

2. Flow Assurance in Offshore Pipelines

Using OLGA, an oil company mitigated hydrate risks and ensured uninterrupted flow in subsea pipelines.

3. Carbon Capture Feasibility

Petro-SIM was used to design and evaluate a CCS system, ensuring compliance with environmental regulations.

Conclusion

Oil and Gas Process Simulation Software is revolutionizing the energy sector by enhancing operational efficiency, safety, and sustainability. With ongoing advancements in technology, the adoption of these tools will continue to grow, enabling the industry to navigate challenges and seize opportunities in an increasingly complex energy landscape. As the demand for cleaner, more efficient energy solutions rises, simulation software will remain a cornerstone of innovation in the oil and gas industry.