In the fast-evolving world of plumbing, durability, safety, and efficiency are more important than ever. Among the many piping solutions available today, PPR Pipes and Fittings have carved a niche for themselves due to their unmatched performance, long service life, and resistance to chemicals and temperature variations. For homeowners, engineers, and infrastructure planners alike, choosing the right piping system can make or break a project. This is where KPT Pipes, a leading Pipes Manufacturing Company in India, takes center stage with its exceptional range of PPR plumbing solutions.

Whether you’re undertaking a residential, industrial, or commercial project, KPT Pipes ensures reliability with high-quality PPR systems that meet global standards. Let’s explore how these pipes are revolutionizing modern plumbing across India.

What are PPR Pipes and Fittings?

PPR (Polypropylene Random Copolymer) pipes are lightweight, non-corrosive thermoplastic pipes known for their resistance to high temperatures and pressure. Combined with specially designed fittings, they offer seamless water flow, leak-proof joints, and minimal maintenance.

Key Features:

- Resistance to corrosion and scaling

- Ability to withstand high temperatures (up to 95°C)

- Leak-proof and joint-free installation with fusion welding

- Long life span of up to 50 years under normal conditions

- Eco-friendly and recyclable material

These features make them the top choice for a wide range of applications — from residential plumbing to industrial fluid systems.

Why Choose KPT Pipes for PPR Pipes and Fittings?

As a trusted Pipes Manufacturing Company in India, KPT Pipes delivers a superior line of PPR pipes crafted with cutting-edge technology and high-grade raw materials. Here’s why they are considered the Best PPR Pipes in India:

1. German Technology, Indian Manufacturing

KPT Pipes uses advanced German technology to manufacture pipes that adhere to international quality standards. This ensures precision, consistency, and strength in every product.

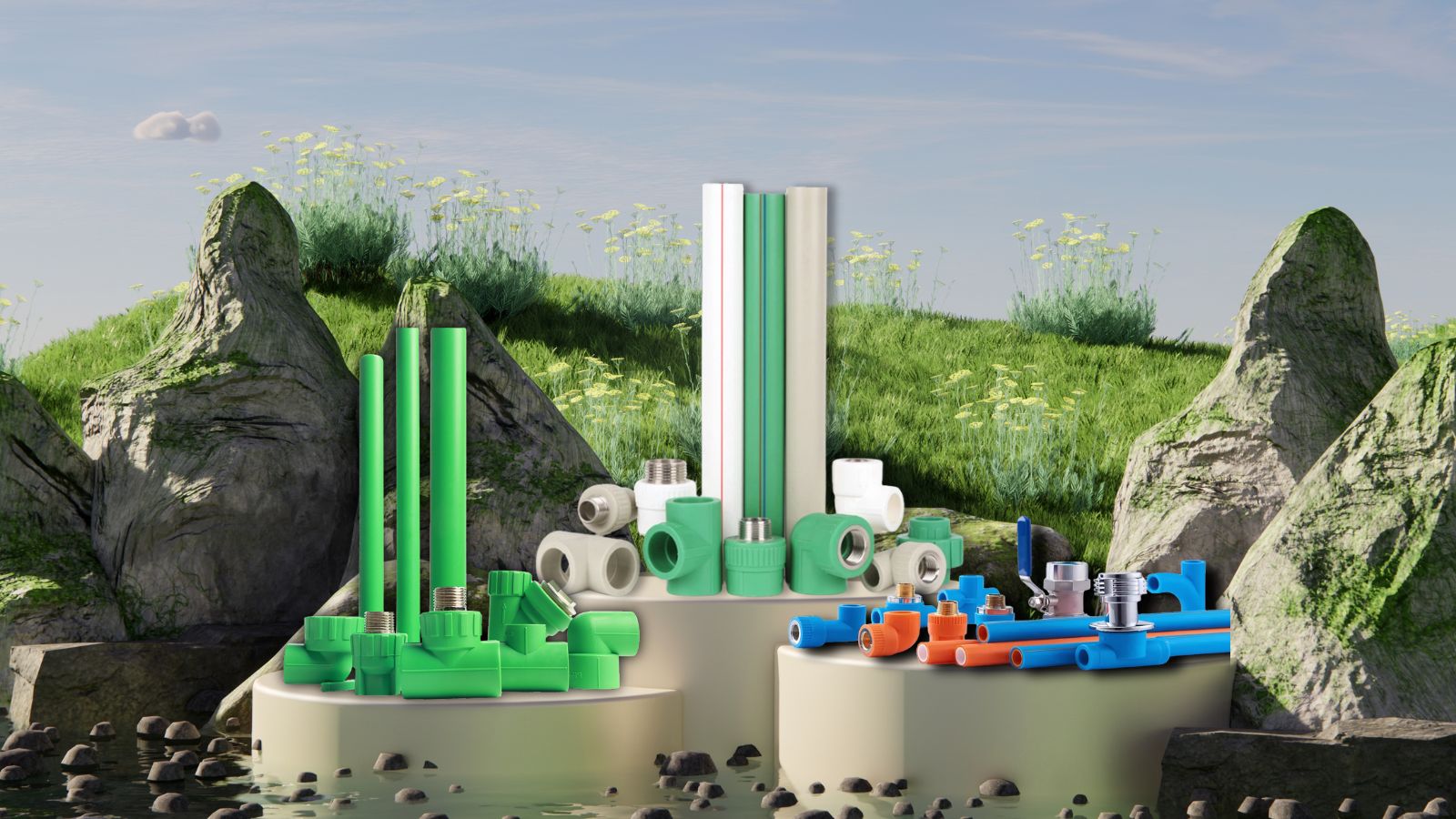

2. Wide Product Range

From Standard PPR pipes to PPR-FR (Fire Retardant) pipes, Glass Fiber Reinforced PPR pipes, and PPR-CT pipes, KPT offers a complete range suited for various applications and environments.

3. Fusion-Welded Fittings

The fittings are fusion welded, creating a monolithic structure that ensures zero leakage, increased safety, and durability.

4. Certifications and Quality Control

KPT Pipes’ manufacturing facilities follow strict quality control protocols. The pipes and fittings are ISO-certified and tested rigorously before reaching the end user.

5. Eco-Conscious Manufacturing

Sustainability is at the core of KPT’s operations. All PPR products are environmentally friendly and recyclable, making them ideal for eco-sensitive projects.

Applications of PPR Pipes and Fittings

PPR Pipes and Fittings are versatile and used across various sectors:

1. Residential Use

Ideal for hot and cold-water systems in homes, bathrooms, kitchens, and rooftop water tanks due to their thermal stability and smooth internal surface.

2. Commercial Buildings

Used in offices, malls, hospitals, and hotels for centralised water supply systems and HVAC applications.

3. Industrial Facilities

Perfect for transporting aggressive chemicals, compressed air, and hot liquids in factories due to their chemical resistance.

4. Agriculture and Irrigation

It can be used in irrigation systems, greenhouse applications, and livestock water supply systems.

5. Food and Pharma

Safe for use in food-grade fluid systems and pharmaceutical plants due to their non-toxic and odourless material composition.

Types of PPR Pipes Available at KPT Pipes

Let’s break down some popular variants of PPR pipes offered by KPT:

1. Standard PPR Pipes

For everyday domestic and commercial applications, these offer excellent chemical resistance and high flow capacity.

2. PPR-AL-PPR Pipes (Composite Pipes)

The aluminium layer provides added strength and thermal expansion control—perfect for hot water supply lines.

3. PPR-FR (Fire Retardant) Pipes

Designed for environments where fire safety is crucial.

4. Glass Fibre Reinforced PPR Pipes

Enhanced mechanical strength and lower thermal expansion — ideal for industrial and high-pressure applications.

5. PPR-CT Pipes

Can handle higher pressures and temperatures, making them suitable for challenging environments.

6. UV-Resistant PPR Pipes

Specially designed for outdoor installations, these pipes resist degradation from sunlight and UV rays.

The Role of Innovation in PPR Pipe Manufacturing

Innovation is the backbone of any reliable piping solution. As a premier Pipes Manufacturing Company in India, KPT Pipes integrates research and development into every step of the production process. This ensures the pipes not only meet but also exceed industry standards.

KPT’s commitment to innovation includes:

- In-house R&D labs for product development

- Continuous upgrading of manufacturing equipment

- Custom piping solutions for large infrastructure projects

Such efforts have positioned KPT Pipes as a pioneer in offering the Best PPR Pipes in India.

Benefits of Using KPT’s PPR Pipes and Fittings

Here’s a quick look at the compelling advantages:

| Benefit | Details |

|---|---|

| Longevity | Up to 50 years of service with minimal degradation |

| Cost-Effective | Low maintenance and reduced installation costs |

| Chemical Resistance | Suitable for transporting chemicals and aggressive fluids |

| Hygiene | Non-toxic and bacteria-resistant, ideal for potable water |

| Leak-Proof Joints | Fusion welding ensures strong, permanent connections |

| Environmental Safety | 100% recyclable and manufactured with eco-friendly practices |

| Noise Reduction | Excellent insulation properties reduce water hammer and noise |

What Makes KPT Pipes the Best PPR Pipes in India?

It’s not just the quality of the pipes but the overall experience KPT delivers — from inquiry to installation. With dedicated customer support, technical guidance, and a nationwide dealer network, KPT ensures a seamless experience for clients of all sizes.

Whether you are an architect, contractor, or project manager, working with KPT Pipes means having a reliable partner who understands the pulse of India’s evolving infrastructure needs.

Conclusion: Build with Confidence with KPT PPR Pipes and Fittings

Choosing the right piping system is a long-term investment in safety, performance, and peace of mind. With a proven track record, unmatched product quality, and technological excellence, KPT Pipes stands tall as the Best PPR Pipes in India.

Whether you’re starting a new construction project or upgrading your existing systems, KPT’s wide range of PPR Pipes and Fittings has the solution you need, manufactured by the leading Pipes Manufacturing Company in India.

Trust in KPT Pipes. Build Smart. Build Strong.

FAQs on PPR Pipes and Fittings

Q1. What makes PPR Pipes better than PVC or copper pipes?

Ans: PPR Pipes offer superior temperature and pressure resistance compared to PVC. Unlike copper pipes, PPR does not corrode, is lighter, and is easier to install with fusion welding. They also provide long-term durability and safety.

Q2. Are PPR pipes safe for drinking water?

Ans: Yes. PPR Pipes are made from non-toxic, food-grade materials that resist bacterial growth. They do not affect drinking water’s taste, odor, or quality.

Q3. How long do KPT PPR Pipes last?

Ans: Under normal usage, KPT’s PPR pipes can last over 50 years, making them a cost-effective and long-term plumbing solution.

Q4. Where can PPR pipes be used?

Ans: They are used in residential plumbing, industrial systems, HVAC lines, agriculture, hospitals, and even food-grade applications.

Q5. Why choose KPT Pipes?

Ans: KPT Pipes delivers advanced plumbing solutions using German technology, strict quality controls, and a wide variety of PPR pipe types tailored to every need — making them one of the Best PPR Pipes in India.