In global logistics, ensuring clean and safe transportation of goods is paramount. Among the many tools designed to protect cargo, container liners stand out as an indispensable solution. These flexible, durable liners create a barrier inside containers, protecting goods from contamination, moisture, and damage. From transporting food-grade products to chemicals, Container liners manufacturers provide customized solutions to meet diverse industry needs.

This article explores the features, benefits, and applications of container liners, focusing on their importance in modern supply chains. We’ll highlight the advantages of Food-grade container liners and flexible container liners, along with answers to common questions about these essential products.

What Are Container Liners?

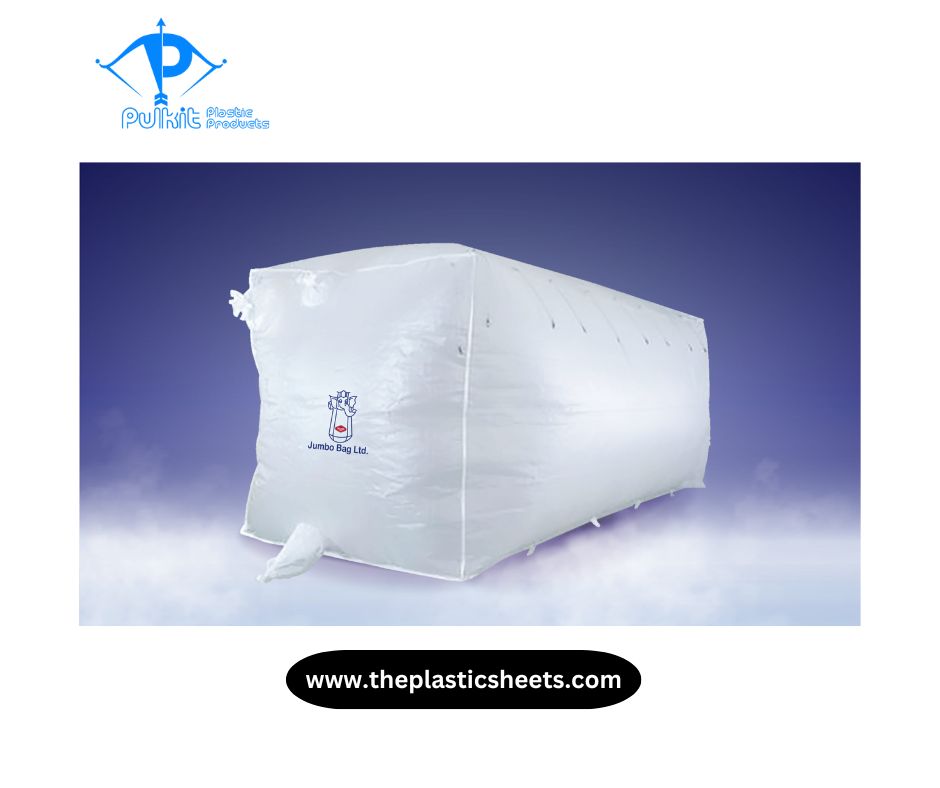

Container liners are large bags or liners made of materials like polyethylene, polypropylene, or multi-layer composites. They are designed to line the interior of standard shipping containers, creating a sealed environment that safeguards goods during transit. Container liners can be tailored to fit different container sizes and are used for bulk cargo such as grains, powders, chemicals, and liquids.

Benefits of Using Container Liners

1. Protection from Contamination

One of the primary functions of container liners is to prevent contamination. Whether shipping food products or chemicals, liners ensure that goods remain clean and uncontaminated by the container’s interior or external factors.

2. Moisture and Temperature Control

High-quality liners provide excellent resistance to moisture, ensuring that goods are protected from humidity and condensation during transit. Specialized liners can also regulate temperature, safeguarding sensitive products.

3. Cost-Effectiveness

By reducing the need for cleaning and maintenance of containers, liners lower operational costs. They also minimize product loss due to contamination or damage, making them a cost-effective solution.

4. Environmental Sustainability

Many Flexible container liners are designed to be recyclable, contributing to eco-friendly shipping practices. This aligns with global efforts to reduce waste and promote sustainable logistics.

5. Easy Installation and Removal

Container liners are lightweight and easy to install, saving time and labor during loading and unloading processes. Their design ensures compatibility with automated systems, enhancing efficiency.

Types of Container Liners

1. Food-Grade Container Liners

Food-grade container liners are specially designed to meet stringent hygiene standards required for transporting consumables. These liners are made from FDA-approved materials, ensuring that food products remain safe and uncontaminated during shipping. They are commonly used for transporting grains, sugar, flour, and other bulk food items.

2. Chemical-Resistant Liners

For industries dealing with hazardous or non-hazardous chemicals, chemical-resistant liners provide a reliable solution. These liners are made from robust materials that can withstand exposure to corrosive substances, ensuring safe and compliant shipping.

3. Dry Bulk Liners

Dry bulk liners are ideal for transporting powdered or granular materials like cement, fertilizers, and resins. These liners are designed to prevent product leakage and ensure efficient unloading.

4. Liquid Bulk Liners

Liquid bulk liners, also known as flexitanks, are used for transporting non-hazardous liquids such as oils, syrups, and juices. They convert standard containers into liquid storage units, offering a cost-effective alternative to traditional tank containers.

5. Customizable Liners

Many container liners manufacturers offer customizable options, allowing businesses to choose liners tailored to their specific needs. Custom features may include anti-static properties, UV resistance, or specialized loading/unloading mechanisms.

Applications of Container Liners

1. Food and Beverage Industry

Food-grade liners are widely used in the food and beverage industry to transport bulk commodities. These liners ensure hygiene and prevent cross-contamination, meeting the high standards of the industry.

2. Chemical Industry

For the safe transportation of chemicals, liners provide a protective barrier that prevents leaks and protects the container from corrosive damage.

3. Agriculture

Farmers and agricultural businesses rely on container liners to transport grains, seeds, and fertilizers efficiently. These liners maintain product quality and prevent losses during transit.

4. Pharmaceutical Industry

The pharmaceutical sector uses container liners to transport raw materials and intermediates. High-quality liners ensure that sensitive products remain uncontaminated and protected.

5. Waste Management

Liners are also used in the waste management sector to transport hazardous and non-hazardous waste safely and in compliance with environmental regulations.

How to Choose the Right Container Liners

1. Assess Material Compatibility

Choose liners made from materials compatible with your cargo. For food products, opt for FDA-approved liners, while for chemicals, select liners with high chemical resistance.

2. Consider Cargo Type

The nature of your cargo will determine the type of liner required. For instance, liquid products need liquid bulk liners, while granular materials require dry bulk liners.

3. Evaluate Environmental Conditions

Consider the environmental conditions your cargo will face during transit. If shipping in hot climates, UV-resistant liners may be necessary. For humid conditions, moisture-resistant liners are essential.

4. Look for Customization Options

If your cargo has unique requirements, work with Container liners manufacturers who offer customizable solutions. Features like anti-static properties or specialized loading mechanisms can enhance efficiency and safety.

5. Check Manufacturer Reputation

Choose manufacturers with a proven track record of delivering high-quality liners. Reliable manufacturers ensure compliance with industry standards and provide consistent quality.

Advantages of Flexible Container Liners

Flexible container liners have gained popularity for their adaptability and performance. Here are some advantages:

- Versatility: Flexible liners can accommodate various cargo types, including powders, grains, and liquids.

- Ease of Use: Lightweight and foldable, these liners are easy to handle and store.

- Cost Savings: They reduce the need for specialized containers, offering significant cost savings.

- Eco-Friendly: Many flexible liners are recyclable, promoting sustainable practices.

- Reduced Risk: By creating a sealed environment, these liners minimize the risk of contamination and product loss.

Conclusion

Container liners are a reliable and cost-effective solution for clean and safe shipping. Whether you’re transporting food-grade goods, chemicals, or agricultural products, choosing the right liner can significantly enhance efficiency and product protection. Trusted container liners manufacturers offer a range of options, from food-grade container liners to flexible container liners, ensuring there’s a solution for every need.

By investing in high-quality liners, businesses can minimize risks, reduce costs, and meet industry standards for safe and sustainable logistics. In today’s competitive market, container liners are more than just a protective barrier—they are a key to ensuring success in global trade.

Frequently Asked Questions (FAQs)

1. Are container liners reusable?

Some container liners are designed for single-use, especially in industries requiring strict hygiene standards. However, certain liners, like those used for non-sensitive cargo, can be reused if properly cleaned and maintained.

2. How do I install container liners?

Installation is straightforward and typically involves securing the liner inside the container using hooks or straps. Many liners come with detailed instructions, and some manufacturers offer installation support.

3. What materials are used to make food-grade container liners?

Food-grade liners are made from FDA-approved polyethylene or polypropylene materials. These materials are non-toxic, odorless, and meet stringent safety standards to ensure the safe transportation of food products.