CNC (Computer Numerical Control) aluminum machining is a critical aspect of modern manufacturing, enabling the creation of highly precise and intricate aluminum components. This technology has significantly transformed industries ranging from aerospace to automotive, electronics, and medical devices, offering manufacturers unparalleled accuracy, speed, and efficiency. In this article, we will explore what CNC aluminum machining is, the benefits it offers, and how it is revolutionizing various industries.

What Is CNC Aluminum Machining?

CNC aluminum machining refers to the process of using computer-controlled machines to cut, mill, drill, or shape aluminum into precise components and parts. The CNC machining process involves the use of a computer program that controls the movement of tools such as drills, mills, and lathes. This process ensures that aluminum parts are produced with high precision and repeatability, making it ideal for complex and detailed designs.

Aluminum, being a lightweight, durable, and highly machinable metal, is commonly used in various applications where strength-to-weight ratios and corrosion resistance are important. CNC machining allows manufacturers to create custom parts from aluminum with excellent surface finishes, tight tolerances, and intricate geometries.

The CNC Machining Process for Aluminum

The CNC machining process for aluminum involves several key steps:

1. Design and Programming

The first step in CNC aluminum machining is designing the part. Engineers and designers use Computer-Aided Design (CAD) software to create a 3D model of the part. Once the design is finalized, the CAD model is converted into a CNC-compatible format using Computer-Aided Manufacturing (CAM) software. The CAM software generates toolpath instructions that guide the CNC machine’s movement, ensuring that the part is machined precisely as designed.

2. Material Selection and Preparation

The next step is to select the appropriate aluminum alloy for the part. Different aluminum alloys offer varying properties such as strength, corrosion resistance, and machinability. Once the material is selected, it is prepared by cutting it into the appropriate size and shape for the machining process.

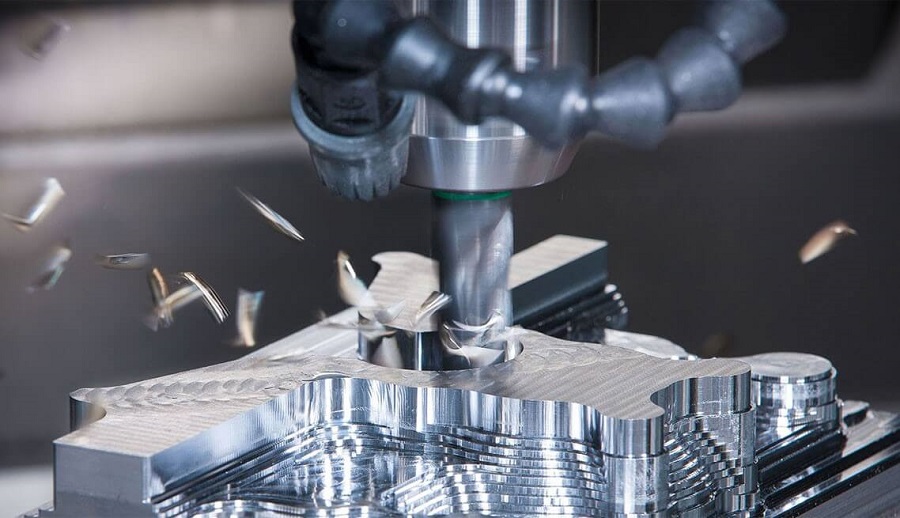

3. Machining

The CNC machine is set up with the necessary tools, such as end mills, drills, and taps, depending on the complexity of the design. The program is loaded into the machine, and the machining process begins. The CNC machine moves along multiple axes, removing material from the aluminum block to create the desired shape. This process can involve operations such as drilling holes, cutting slots, milling surfaces, and turning the material to achieve the final form.

4. Quality Control

After the part is machined, it undergoes thorough inspection and quality control procedures to ensure that it meets the required specifications. This can include measuring the part’s dimensions, checking the surface finish, and verifying that the material properties are consistent with the design. If necessary, the part is re-machined to meet tolerances.

Benefits of CNC Aluminum Machining

CNC aluminum machining offers numerous advantages that make it an ideal choice for many manufacturing applications. Some of the key benefits include:

1. Precision and Accuracy

CNC machines are capable of producing parts with extremely tight tolerances, often to within a few thousandths of an inch. This level of precision is crucial in industries such as aerospace, automotive, and medical devices, where even the smallest variations can affect the performance and safety of the product. The automation provided by CNC machining ensures that each part is produced with consistent quality, reducing the risk of human error.

2. Complex Geometries

One of the standout features of CNC aluminum machining is its ability to produce highly complex geometries that would be difficult or impossible to achieve with manual machining techniques. CNC machines can handle intricate designs, curved surfaces, and detailed features with ease, making them ideal for industries that require precision-engineered components, such as aerospace and electronics.

3. Efficiency and Speed

CNC aluminum machining is highly efficient, allowing manufacturers to produce large quantities of parts in a short amount of time. The automation provided by CNC machines reduces the need for manual labor and speeds up the production process. Additionally, since the machines are capable of running unattended for long periods, manufacturers can achieve high production rates, making CNC machining an ideal solution for both low and high-volume production.

4. Versatility

CNC aluminum machining can be used to create a wide range of products, from small and simple parts to large, complex components. The versatility of CNC machines allows manufacturers to work with different types of aluminum alloys, as well as other materials such as plastics and composites. This flexibility makes CNC machining suitable for various industries, including aerospace, automotive, medical, and electronics.

5. Reduced Waste

Since CNC machines are highly precise, they minimize material waste by making accurate cuts and ensuring that only the necessary amount of aluminum is removed. This helps reduce the cost of raw materials and is more environmentally friendly by minimizing scrap material.

6. Repeatability

Once a CNC machining program is created and tested, it can be used to produce an unlimited number of identical parts. This repeatability ensures that each part is manufactured to the exact same specifications, which is essential in industries where consistency is key.

Industries That Benefit from CNC Aluminum Machining

CNC aluminum machining is a versatile process that finds applications across numerous industries. Some of the primary sectors that benefit from this technology include:

1. Aerospace

The aerospace industry relies heavily on CNC aluminum machining for the production of lightweight, high-strength components such as aircraft frames, wings, and engine parts. Aluminum’s excellent strength-to-weight ratio makes it a preferred material for aircraft components, and CNC machining ensures that these parts meet the stringent safety and performance standards required in aerospace manufacturing.

2. Automotive

CNC aluminum machining is used extensively in the automotive industry to manufacture parts such as engine components, transmission housings, and suspension parts. The lightweight nature of aluminum helps improve fuel efficiency and performance, and CNC machining ensures that these parts are produced with high precision and durability.

3. Medical Devices

Medical device manufacturers rely on CNC aluminum machining to create highly precise components for surgical instruments, diagnostic equipment, and implants. Aluminum’s biocompatibility and corrosion resistance make it ideal for medical applications, and CNC machining allows manufacturers to produce complex, high-precision parts with tight tolerances.

4. Electronics

The electronics industry uses CNC aluminum machining to produce enclosures, heat sinks, and structural components for devices such as smartphones, computers, and communication equipment. Aluminum’s excellent thermal conductivity makes it ideal for dissipating heat in electronic devices, and CNC machining ensures that these parts are manufactured with the required precision.

5. Defense and Military

CNC aluminum machining is critical for producing military and defense components, such as weapons parts, drones, and armor plating. The ability to machine high-strength aluminum alloys to precise specifications is essential for the reliability and performance of defense equipment.

6. Consumer Products

From bicycles to kitchen appliances, CNC aluminum machining is used to create a wide range of consumer products. Aluminum’s lightweight and attractive appearance make it an ideal material for products that need to be both functional and aesthetically pleasing.

Challenges in CNC Aluminum Machining

While CNC aluminum machining offers numerous benefits, there are also some challenges associated with the process:

1. Tool Wear

Aluminum is a soft material, which can lead to significant wear on cutting tools over time. Frequent tool changes may be necessary, particularly during high-volume production runs, to maintain the precision and quality of the machined parts.

2. Material Variability

Different aluminum alloys can have varying properties, and selecting the right material for a given application is crucial. Machining certain alloys can be more difficult than others, requiring specialized tools or adjustments to machining parameters.

3. Complex Setup

For complex parts with intricate features, CNC machining setups can be time-consuming and require careful programming. A lack of expertise in programming and machine operation can lead to inefficiencies or errors in the machining process.

Conclusion

CNC aluminum machining has transformed manufacturing by offering unmatched precision, speed, and versatility. The ability to produce complex, high-quality components quickly and efficiently makes it an invaluable tool across a wide range of industries, including aerospace, automotive, medical devices, and consumer electronics. As technology continues to evolve, CNC aluminum machining will play an even more prominent role in the development of advanced products and innovations. Whether for prototyping or full-scale production, CNC aluminum machining offers a reliable and cost-effective solution for manufacturers seeking to achieve the highest standards in product quality and performance.