The global adhesive equipment market size attained a value of nearly USD 40.14 billion in 2024. The market is further estimated to grow in the forecast period of 2025-2034 at a CAGR of 5.6% to reach a valuation of about USD 65.55 billion by 2034. This growth is largely driven by increasing industrial automation, demand for precision adhesive application, and advancements in adhesive technologies across various sectors. As the demand for high-performance adhesive equipment continues to rise, it is essential to understand the key factors influencing this market, including product innovations, regional developments, and evolving applications in diverse industries.

Market Overview

Adhesive equipment plays a critical role in industries where bonding and sealing are essential for production processes. From packaging and automotive to electronics and construction, the need for efficient, high-performance adhesive application systems is becoming more pronounced. The market for adhesive equipment includes products such as hot melt applicators, adhesive controllers, pneumatic applicators, and cold glue systems, each catering to the unique demands of industrial sectors. With increasing manufacturing capabilities and technological advancements in automation, adhesive equipment is now essential for improving productivity and ensuring high-quality bonding results.

The adhesive equipment market is poised for significant growth, with the rising trend of automation and sustainability pushing demand for more advanced, eco-friendly, and efficient adhesive systems. As industries look to optimize production processes, the adoption of adhesive technologies that offer precision, speed, and versatility will continue to expand.

Market Size and Growth Projections

In 2024, the global adhesive equipment market was valued at approximately USD 40.14 billion, and it is set to grow at a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2025 to 2034. This growth trajectory indicates that the market will reach an estimated valuation of USD 65.55 billion by 2034. Several factors are contributing to this growth, including the expansion of manufacturing sectors, increased demand for high-performance adhesives, and the growing importance of automation and precision in industrial operations.

The demand for adhesive equipment is particularly strong in sectors that require high-quality, durable, and precise adhesive applications, such as automotive manufacturing, electronics assembly, packaging, and construction. Furthermore, the trend toward sustainability and eco-friendly solutions is creating new opportunities for the development of innovative adhesive products and equipment.

Market Segmentation

The adhesive equipment market can be segmented based on product types, applications, and regions. Below, we explore the major product categories and their roles in the market.

By Product

Industrial Hot Melt Equipment

Industrial hot melt adhesive equipment is widely used in packaging, automotive, and construction industries due to its ability to provide strong bonding in a fast and efficient manner. This equipment helps in applying hot melt adhesives that harden quickly upon cooling, making them ideal for high-speed production lines. With the increasing demand for packaging solutions, the market for hot melt adhesive equipment is projected to grow significantly. Manufacturers are continuously innovating in this segment to offer products that enhance operational efficiency while minimizing material waste.

Adhesive Controllers

Adhesive controllers are used to regulate the application of adhesives, ensuring precise and consistent results. These systems are crucial in high-precision industries such as electronics, where accurate adhesive placement is required for assembling components like sensors and screens. With the increasing emphasis on automation and the growing need for precision in manufacturing processes, adhesive controllers are gaining prominence in industries across the globe.

Pneumatic Adhesive Applicators

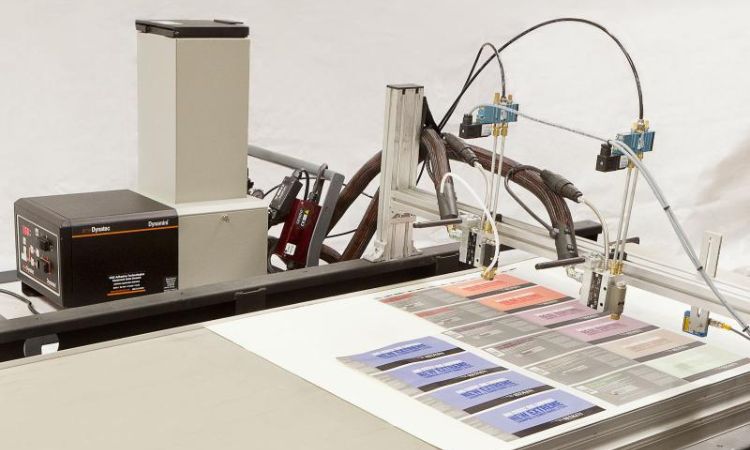

Pneumatic adhesive applicators are used in manufacturing processes that require reliable and controlled adhesive dispensing. These systems utilize air pressure to apply adhesives consistently, making them suitable for industries like automotive and packaging. As automation continues to dominate manufacturing, the demand for pneumatic adhesive applicators is expected to rise, driven by the need for speed, accuracy, and reduced labor costs.

Cold Glue Applicators

Cold glue applicators are typically used for paper and packaging applications where a cold adhesive is preferred. These systems are ideal for industries that require strong bonds without the heat-related risks associated with hot melt equipment. Cold glue systems are particularly beneficial in the packaging industry, where cost-effective bonding solutions are essential. The market for cold glue applicators is expected to continue growing as the demand for sustainable packaging solutions increases.

Adhesive Pumping Systems

Adhesive pumping systems are designed to deliver adhesives in controlled amounts, ensuring consistent and efficient application. These systems are vital in industries that require large-scale adhesive application, such as automotive assembly lines and high-volume packaging processes. As manufacturers continue to focus on improving efficiency and reducing waste, the demand for adhesive pumping systems is expected to increase.

Adhesive Application Guns

Adhesive application guns are widely used in both industrial and DIY applications. These tools are ideal for small-scale adhesive application, offering flexibility and precision in tasks such as packaging, electronics assembly, and furniture production. The increasing trend of home-based crafting and DIY projects, along with industrial adoption, will likely fuel continued demand for adhesive application guns in the coming years.

By Application

Packaging

The packaging industry is one of the largest consumers of adhesive equipment, with applications ranging from carton sealing and labeling to bottle labeling and box assembly. Adhesive equipment helps improve production speed and product quality, making it indispensable for packaging operations. The growing global e-commerce industry is driving the demand for adhesive equipment, as packaging needs to meet the increasing demands of fast delivery and secure product handling.

Automotive

In the automotive sector, adhesive equipment is used to apply adhesives for bonding body panels, interior parts, and windows, among other components. Adhesives are becoming an essential part of vehicle manufacturing, especially for lightweight vehicle designs that require high-strength bonds. The rise of electric vehicles (EVs) and the shift towards lighter materials further increase the demand for advanced adhesive equipment in automotive manufacturing.

Electronics

The electronics industry relies heavily on adhesive equipment for assembling devices such as smartphones, computers, and televisions. Adhesives are used for bonding components like screens, semiconductors, and sensors. The increasing miniaturization of electronic devices and the growing demand for precision and reliability in manufacturing processes are driving the adoption of advanced adhesive application equipment in this sector.

Construction

In construction, adhesive equipment is used for various applications, including flooring, wall paneling, and insulation. With the push for eco-friendly and energy-efficient buildings, the demand for adhesives that provide strong bonds without harmful emissions is growing. The construction industry’s increasing focus on sustainability and green building materials presents a significant opportunity for adhesive equipment manufacturers to innovate and cater to these changing needs.

Other Industries

Adhesive equipment is also used in other industries such as healthcare, textiles, and furniture manufacturing. In healthcare, adhesive systems are essential for packaging medical devices and pharmaceuticals, ensuring safety and product integrity. The textile industry uses adhesives in garment production, while the furniture industry relies on adhesives for assembly processes.

Regional Analysis

North America

North America, particularly the U.S., holds a significant share of the global adhesive equipment market. The strong manufacturing base, especially in the automotive and electronics sectors, is driving the demand for adhesive equipment. The growth of the packaging industry, alongside advancements in automation, further contributes to the market expansion in the region.

Europe

Europe is home to many key players in the adhesive equipment market, with countries like Germany, the UK, and France leading the way. The automotive industry in Germany and the growing demand for sustainable packaging solutions are significant growth drivers for adhesive equipment in the region. Additionally, the push for environmentally friendly adhesives is creating new market opportunities in Europe.

Asia Pacific

Asia Pacific is the fastest-growing region for adhesive equipment, driven by rapid industrialization and urbanization, particularly in countries like China, India, and Japan. The increasing demand for packaging, automotive, and electronics products in the region is propelling the adoption of adhesive technologies. China, in particular, is a key player in the global adhesive equipment market due to its dominant manufacturing sector.

Latin America and Middle East & Africa

In Latin America, the adhesive equipment market is expanding as industries like automotive and packaging continue to grow. The Middle East and Africa also present emerging opportunities for adhesive equipment manufacturers, particularly in construction and infrastructure projects.

Market Dynamics

Drivers

- Technological Advancements: The continuous innovation in adhesive equipment, including automation, precision systems, and eco-friendly solutions, is driving market growth.

- Growing Manufacturing Industries: Expansion in automotive, electronics, and packaging industries globally is increasing the demand for adhesive equipment.

- Sustainability Trends: The shift toward sustainable materials and eco-friendly adhesives is creating opportunities for manufacturers to innovate.

Restraints

- High Initial Investment: The cost of advanced adhesive application equipment may deter small and medium-sized enterprises (SMEs) from adopting these technologies.

- Environmental Concerns: Regulatory pressures regarding the use of certain chemicals in adhesives and equipment may impact the market.

Opportunities

- Automation: The rise of automation in manufacturing processes is driving the demand for adhesive equipment that offers speed, precision, and efficiency.

- Emerging Markets: The growing industrial base in developing regions like Asia Pacific and Latin America presents opportunities for market expansion.

Threats

- Competition: The adhesive equipment market is highly competitive, with several established players dominating the market. Smaller companies may struggle to differentiate themselves.

- Alternative Technologies: New bonding technologies, such as welding and mechanical fastening, could compete with adhesives in some industries.

Competitive Landscape

The adhesive equipment market is highly competitive, with leading players such as Nordson Corporation, Graco Inc., ITW Dynatec, and others at the forefront. These companies focus on product innovation, strategic partnerships, and acquisitions to strengthen their market position. Additionally, smaller, specialized players are entering the market with innovative, high-performance solutions to meet the growing demand for precise and sustainable adhesive applications.