“Executive Summary Factory Automation Market Size and Share: Global Industry Snapshot

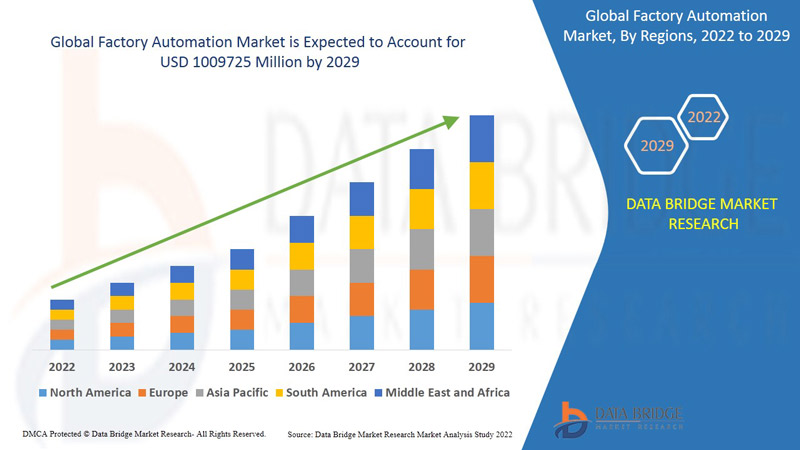

Data Bridge Market Research analyses the market to rise up to the USD 1009725 million by 2029 and to grow at a CAGR of 9.60% in the above-mentioned forecast period.

For an actionable market insight and lucrative business strategies, a faultless market research report has to be there. The credible Factory Automation Market report covers all the studies and estimations that are involved in the method of standard market research analysis. This market report endows with a profound overview of product specification, technology, product type and production analysis by considering most important factors such as revenue, cost, and gross margin. Factory Automation Market report is a window to the Factory Automation Market industry which defines properly what market definition, classifications, applications, engagements and market trends are.

An all-inclusive Factory Automation Market research report comprises of different industry verticals such as company profile, contact details of manufacturer, product specifications, geographical scope, production value, market structures, recent developments, revenue analysis, market shares and possible sales volume of the company. The market insights acquired through this market research report facilitates more defined understanding of the market landscape, issues that may interrupt in the future, and ways to position specific brand brilliantly. A market overview is given in terms of drivers, restraints, opportunities and challenges where each of this parameter is studied scrupulously. Factory Automation Market report works as a superb guide for actionable ideas, enhanced decision-making and better business strategies.

Stay informed with our latest Factory Automation Market research covering strategies, innovations, and forecasts. Download full report: https://www.databridgemarketresearch.com/reports/global-factory-automation-market

Factory Automation Market Trends & Analysis

Segments

– Type: The factory automation market can be segmented based on type into programmable logic controller (PLC), distributed control system (DCS), human-machine interface (HMI), supervisory control and data acquisition (SCADA), manufacturing execution system (MES), and others. PLCs are widely used in factory automation for controlling machinery and processes, while DCS integrates various control elements into a single automated system. HMI allows operators to interact with the machines, SCADA monitors and controls the processes, and MES provides real-time production data and analytics.

– End-User: This market segment includes automotive, food & beverages, pharmaceuticals, chemical, oil & gas, and others. The automotive industry is a major end-user of factory automation, adopting advanced technologies for improved efficiency and productivity. The food & beverages sector utilizes automation for quality control and monitoring processes. Pharmaceuticals rely on automation for precise manufacturing processes, while the oil & gas industry uses it for remote monitoring and control.

– Region: Geographically, the factory automation market is divided into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is a significant market due to the presence of key manufacturing hubs like China, Japan, and South Korea. North America and Europe are also prominent regions with a high adoption rate of automation in industries.

Market Players

– Siemens AG: A leading player in the factory automation market, Siemens offers a wide range of automation solutions including PLCs, DCS, HMI, and SCADA systems. The company focuses on innovation and digitalization to provide cutting-edge automation technologies to various industries.

– Rockwell Automation, Inc.: Another key player, Rockwell Automation specializes in industrial automation and information solutions. The company provides integrated control systems, software, and services for enhancing manufacturing processes.

– ABB Ltd.: ABB is a global leader in robotics, power, and automation technologies. The company offers automation products and services for various industries, ensuring increased productivity and efficiency.

– Mitsubishi Electric Corporation: Mitsubishi Electric is known for its advanced automation products such as PLCs, HMIs, and servo systems. The company focuses on developing smart manufacturing solutions for optimizing production processes.

– Schneider Electric SE: Schneider Electric provides a comprehensive range of automation solutions including PLCs, DCS, and SCADA systems. The company aims to help industries achieve sustainable growth through efficient automation practices.

In conclusion, the global factory automation market is driven by the demand for increased efficiency, productivity, and quality in manufacturing processes across various industries. Key players in the market are continuously innovating and expanding their product offerings to cater to the evolving needs of the industry. With the rise of Industry 4.0 and smart manufacturing, the factory automation market is expected to witness significant growth in the coming years.

One emerging trend in the factory automation market is the increasing adoption of collaborative robots, also known as cobots. These robots are designed to work alongside human operators in a shared workspace, enhancing flexibility and productivity on the factory floor. Cobots are equipped with advanced sensor technology and AI capabilities, allowing them to safely interact with humans and adapt to changing production requirements. This trend is driven by the need for agile manufacturing systems that can quickly respond to fluctuating consumer demand and product customization requirements.

Another significant development in the factory automation market is the integration of Internet of Things (IoT) technology into automation systems. IoT enables machines and devices to communicate and share data in real-time, leading to improved monitoring, predictive maintenance, and overall operational efficiency. By connecting sensors, actuators, and other equipment to the internet, manufacturers can gather valuable insights into their production processes and make data-driven decisions to optimize performance and reduce downtime. The adoption of IoT in factory automation is expected to continue growing as companies seek to create smart factories with interconnected and autonomous systems.

Furthermore, sustainability and environmental consciousness are becoming key drivers in the factory automation market. Manufacturers are increasingly focusing on energy-efficient and eco-friendly automation solutions to reduce their carbon footprint and comply with stringent environmental regulations. Sustainable automation practices not only help companies save on energy costs but also contribute to building a greener and more sustainable future. As a result, market players are developing innovative technologies such as energy-efficient motors, regenerative drives, and smart energy management systems to support eco-friendly manufacturing processes.

Moreover, the COVID-19 pandemic has accelerated the adoption of automation in manufacturing as companies look to minimize human contact and ensure business continuity in the face of disruptions. The pandemic highlighted the importance of resilience and flexibility in manufacturing operations, leading many firms to invest in automation technologies for increased agility and risk mitigation. As a result, the factory automation market is witnessing a surge in demand for automated systems that can enhance remote monitoring, predictive maintenance, and supply chain resilience.

In conclusion, the factory automation market is undergoing rapid transformation driven by emerging trends such as collaborative robots, IoT integration, sustainability initiatives, and the impact of the COVID-19 pandemic. As manufacturers strive to improve operational efficiency, productivity, and sustainability, the demand for advanced automation solutions is expected to continue growing. Market players will need to innovate and adapt to these evolving trends to stay competitive and meet the changing needs of the industry.One emerging trend in the factory automation market is the shift towards digital twins and virtual commissioning. Digital twins are virtual replicas of physical systems, processes, and products that can simulate and predict their behavior in real-time. By creating digital twins of manufacturing facilities, companies can optimize production processes, identify potential issues, and test new solutions without disrupting actual operations. Virtual commissioning, on the other hand, involves using digital models to validate and optimize control strategies before implementing them in a physical environment. This trend is driven by the need for cost-effective and efficient ways to design, commission, and operate automated systems in the era of Industry 4.0.

In addition to digital twins, the factory automation market is witnessing a rise in the adoption of edge computing for real-time data analysis and decision-making at the point of production. Edge computing involves processing data closer to its source, enabling faster response times and reducing latency in industrial automation systems. By deploying edge devices and gateways on the factory floor, manufacturers can leverage the power of data analytics and AI algorithms to optimize processes, detect anomalies, and improve overall equipment effectiveness. This trend aligns with the increasing demand for predictive maintenance, quality control, and performance optimization in smart manufacturing environments.

Furthermore, the convergence of artificial intelligence (AI) and machine learning with automation technologies is reshaping the factory automation landscape. AI-powered automation solutions can learn from data, adapt to changing conditions, and make intelligent decisions autonomously. Machine learning algorithms enable predictive maintenance by analyzing equipment data to forecast potential failures and schedule maintenance activities proactively. AI also plays a crucial role in optimizing production scheduling, resource allocation, and supply chain management in complex manufacturing operations. As AI continues to mature, its integration with automation systems will drive efficiency gains, cost reductions, and operational excellence in the factory automation market.

Moreover, cybersecurity is a growing concern in the factory automation industry as interconnected systems become more vulnerable to cyber threats and attacks. With the proliferation of IoT devices, cloud-based platforms, and networked equipment, manufacturers are facing heightened risks of data breaches, sabotage, and operational disruptions. Cybersecurity measures such as encrypted communication, access controls, intrusion detection systems, and network segmentation are critical to safeguarding automated systems from cybersecurity threats. As the reliance on digital technologies increases, ensuring the security and integrity of factory automation systems will be paramount for maintaining operational continuity and protecting sensitive information.

In conclusion, the factory automation market is evolving rapidly with the emergence of trends such as digital twins, edge computing, AI integration, and cybersecurity resilience. Manufacturers are embracing these technologies to drive innovation, enhance productivity, and mitigate risks in their automated processes. As the industry moves towards greater automation, connectivity, and intelligence, companies that leverage these trends effectively will gain a competitive advantage and thrive in the dynamic market landscape. It is essential for market players to stay abreast of these developments and invest strategically in advanced automation solutions to address changing customer demands and market dynamics.

Learn about the company’s position within the industry

https://www.databridgemarketresearch.com/reports/global-factory-automation-market/companies

Factory Automation Market Overview: Strategic Questions for Analysis

- Which technologies are enhancing customer experience?

- How do climate conditions affect product demand?

- What is the return rate of products in the Factory Automation Market?

- How are companies building brand awareness?

- What role do trade shows play in this Factory Automation Market?

- How has the B2B segment evolved?

- What partnerships exist with logistics providers?

- Which region has the highest customer lifetime value?

- How do brands manage customer feedback?

- What are the top loyalty-building tactics?

- What marketing channels have the highest ROI?

- How is CSR (Corporate Social Responsibility) leveraged?

- What’s the conversion rate in digital campaigns?

- How are enterprises managing inventory?

Browse More Reports:

Europe Tunable Laser Market

Middle East and Africa Tunable Laser Market

North America Tunable Laser Market

Asia-Pacific Transplant Diagnostics Market

Europe Transplant Diagnostics Market

Middle East and Africa Transplant Diagnostics Market

North America Transplant Diagnostics Market

Europe Topical Drug Delivery Market

Asia-Pacific Topical Drug Delivery Market

North America Topical Drug Delivery Market

Middle East and Africa Surgical Operating Microscopes Market

Asia-Pacific Surgical Operating Microscopes Market

Europe Surgical Operating Microscopes Market

North America Surgical Operating Microscopes Market

Asia-Pacific Surgical Instrument Tracking Systems Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

“