1. The Stuff Nobody Talks About—but Everyone Depends On

Ever notice how people rave about engines, wings, fancy avionics… but barely whisper about the fasteners holding the whole thing together? Yeah. Aerospace fastener suppliers live in that quiet corner. Same with any turned parts manufacturer. They’re doing the invisible work. The “don’t screw this up” work. And honestly, that’s where the magic is.

Small parts. Big consequences. Always has been.

2. A Closer Look at These Unseen Heroes

Let’s get something straight. A fastener isn’t “just a bolt.” And a turned part isn’t “just metal on a lathe.” These components sit inside aircraft, satellites, drones—places where failure isn’t a joke.

Every thread, every micrometer, has a purpose. Aerospace fastener suppliers who know their stuff treat tolerances like gospel, because even a hair off can turn into a major issue at 35,000 feet.

3. Why Aerospace Needs a Different Breed of Supplier

Aerospace parts aren’t built with “good enough.” They’re built with “don’t fail, ever.” That’s why working with suppliers who specialize in this industry matters. They understand materials that don’t warp under heat, or fail under vibration, or corrode from the slightest environmental mess.

And yeah, that takes experience. And the right machines. And people who still care about craftsmanship.

4. Precision Turning: Not Just Cutting Metal

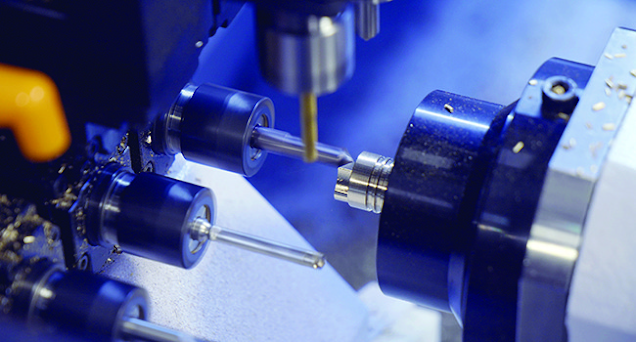

People outside manufacturing think turning is simple. Spin the bar, cut the shape, done. But any serious turned parts manufacturer will tell you, that’s cute but wrong.

Modern turning—especially for aerospace—is almost surgical. Complex geometries. Exotic alloys. Tight tolerances that feel absurd if you’ve never worked in the field. You’re making pieces that fit into systems that cost millions. Sometimes billions. You don’t wing that.

5. Why CNC Swiss Machining Changed the Game

Swiss-style CNC machines didn’t show up to play. They showed up to win. These machines hold material differently, cut differently, and let manufacturers push tolerances to places old-school lathes just couldn’t go.

For tiny, mission-critical parts, Swiss machining is the gold standard. Aerospace fastener suppliers rely on it because it produces parts that don’t just “fit”—they lock in place like they were born there.

6. The Real Stress: Consistency, Not Just Accuracy

You can make one perfect part by accident. Happens all the time. What separates a real turned parts manufacturer from a pretender is repeatability.

Can you make 5,000 perfect pieces?

Can you make them the same in July heat and December cold?

Can you do it when an engineer tweaks a dimension at the last minute?

That’s the battlefield, right there.

7. Materials Aren’t Just Materials

Titanium behaves like it has an attitude. Stainless steels are stubborn in their own way. Aluminum’s soft until it suddenly isn’t.

Aerospace materials are tricky, because they’re designed that way. Strong. Heat-resistant. Lightweight. But they fight back during machining.

So the suppliers who know how to work with these metals? They’re worth their weight in—well—titanium.

8. The Surprising Cost of Cutting Corners

Ever hear the phrase “cheap becomes expensive”? In aerospace, it becomes dangerous too. Bad fasteners can shake loose. Poorly machined parts can crack. Wrong materials can corrode quietly until they fail loudly.

Aircraft don’t fall out of the sky from the big stuff.

They fail from the tiny things someone ignored.

That’s why choosing the right suppliers isn’t an afterthought. It’s part of the safety chain.

9. What Modern Aerospace Clients Actually Want

They want reliability, sure. But not just in the parts—also in communication, deadlines, documentation. Aerospace buyers hate surprises.

They want transparency.

They want suppliers who don’t miss specs, miss deadlines, or miss emails.

It’s not glamorous, but it’s the truth. A good fastener supplier is as dependable as gravity: always there, steady, predictable.

10. Automation Helps, but People Still Run the Show

Everyone loves talking automation. CNC software. Robotic loading. Inspection scanners. Great tools.

But ask any veteran machinist—they’ll tell you the machines don’t save the day. People do.

Machining aerospace turned parts isn’t a button-press job. You need humans who know how to listen to a spindle, notice a chip pattern, catch a dimension drifting before it becomes expensive.

Experience still matters. Big time.

11. Why Customers Stick with the Same Few Suppliers

Real talk? Loyalty in aerospace isn’t emotional—it’s practical. When someone proves they can hit tolerances, own deadlines, and not freak out during engineering changes… buyers hold onto them.

Because finding someone new takes time.

And trust doesn’t grow overnight.

Aerospace fastener suppliers who consistently deliver become long-term partners, not one-off vendors.

12. The Future: Smaller Parts, Bigger Expectations

Every year, aerospace designs get more compact, more efficient. That means the parts get smaller. Tolerances get tighter. Materials get tougher.

Turned parts manufacturer has to adapt—faster tooling, better cutting strategies, smarter machining centers, cleaner inspection data.

The bar keeps rising. And the companies that invest in staying ahead? Those are the ones shaping the next generation of flight hardware.

Final Thoughts (And a Nudge Forward)

If you’re in aerospace—whether you’re building flight controls, satellite components, engine systems, whatever—you already know small parts carry the biggest weight.

So partner with suppliers who understand that.

Suppliers who obsess over precision.

Suppliers who don’t flinch at tight tolerances or crazy alloys.

If you want that level of craftsmanship and consistency, reach out to Allied Technologies International, Inc to start.

FAQs

Q1: What makes aerospace fastener suppliers different from standard industrial suppliers?

Aerospace suppliers work with tighter tolerances, certified materials, and extremely strict quality standards. Every part has to survive vibration, heat, pressure, and time without failing.

Q2: Why are turned parts so important in aerospace?

Turned components sit in critical systems—fuel, hydraulics, controls, sensors. They often have small, complex geometries that must fit perfectly every time.

Q3: Are Swiss-machined parts better for aerospace?

For small, precise components—absolutely. Swiss machining delivers the accuracy and consistency aerospace applications demand.

Q4: How do I choose the right supplier?

Look for experience, certifications, material knowledge, consistency, and a track record of making aerospace-grade components without excuses.

Q5: Why partner with a single supplier long-term?

Consistency and trust. When a supplier already knows your standards, drawings, materials, and timelines, everything moves faster and smoother.