Whether it’s a fishing trip at dawn or a weekend cruise, your boat’s performance depends on reliable power—and that starts with your battery cable wire setup. Yet in marine environments, salt, heat, and vibration take a serious toll on electrical systems. Without regular maintenance, even the best marine-grade battery cable won’t hold up as long as it should.

This guide helps boat owners, fleet operators, and marine technicians stay ahead of common cable issues with simple, actionable steps.

Routine Inspection Tips for Marine Battery Cable Wire

Out of sight often means out of mind—but in the case of battery cables, a visual inspection goes a long way. Most marine battery cable problems don’t appear suddenly—they build up over time.

Here’s what to keep on your checklist:

- Check cable jackets for signs of wear, such as cracking, swelling, or abrasion.

- Look for loose or greenish connections, which indicate corrosion buildup.

- Test for stiffness—a high-quality battery cable should remain flexible even after years of use.

Plan to check your battery cables every three to six months, especially before long trips or heavy seasonal use. If your boat sees frequent exposure to saltwater spray, it’s worth doing this more often.

Cleaning Terminals Without Compromising Wire Integrity

Terminal corrosion is one of the leading causes of voltage drop and battery failure in boats. The fix? Regular, safe cleaning.

Use these basic steps:

- Disconnect the battery before doing any work.

- Neutralize corrosion using a mix of baking soda and water. Apply with a small brush.

- Use a wire terminal brush to scrub contact points without overdoing it.

- Avoid water intrusion by applying a corrosion inhibitor and sealing with adhesive-lined heat shrink.

Keep in mind: Marine battery cable wire is usually made from tinned copper, which resists corrosion better than bare copper. Still, prevention is key—especially when docked in humid, salt-heavy environments.

Routing Battery Cables in Tight Hull Spaces Without Damage

Proper routing prevents chafing, minimizes voltage drop, and helps extend the overall life of your battery cable installation.

Tips for tight spaces:

- Use grommets or cable clamps when passing through bulkheads or near sharp edges.

- Avoid 90-degree bends, especially near terminals. Cables should curve gently.

- Keep wires away from heat sources like exhaust manifolds or uninsulated engine parts.

- Label each cable to save troubleshooting time later on.

Well-supported, clearly routed battery cables also make future upgrades easier—and safer.

Signs of Heat Damage, Chafing, and Corrosion You Shouldn’t Ignore

Small problems can escalate quickly if they go unchecked. Catching early signs of damage will save you from costly electrical failures—or worse, fires.

Watch for these warning signs:

- Melting or discoloration near terminal ends

- Burnt smells coming from the battery box

- Exposed copper strands or brittle insulation

- Cracked lug crimps that no longer grip the cable properly

When in doubt, don’t patch—replace. High-quality marine battery cable is easy to work with and designed to hold up under the tough conditions marine systems face daily.

Upgrading Old Battery Cables When It’s Time and What to Choose

If your boat’s battery cable is more than 5–7 years old—or if you’ve recently added new electronics—it might be time to upgrade.

What to look for:

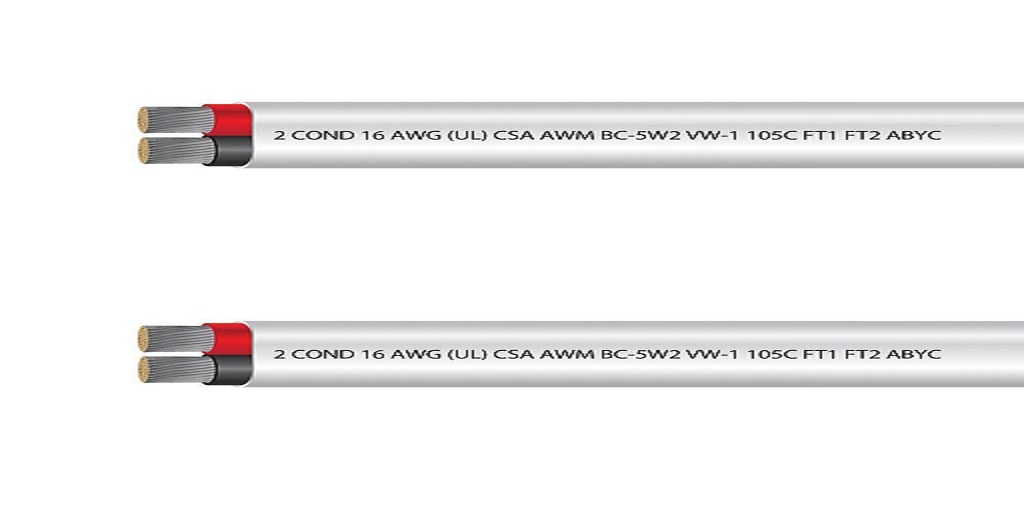

- Tinned copper conductors for superior corrosion resistance

- UL 1426-rated marine battery cable that meets strict safety standards

- Flexible, fine-strand wire construction for easy routing and better vibration resistance

- Properly sized cable to reduce voltage drop (especially important for longer runs)

Going with the right supplier also matters. A U.S.-made battery cable offers traceability, consistent quality, and assurance that you’re getting cable built to last.

A Little Upkeep Goes a Long Way

Protecting your battery cable wires is more than just preventative maintenance—it’s a smart way to keep your boat safer and running at its best. Whether you’re troubleshooting, upgrading, or doing seasonal checks, investing time in proper battery cable care is always worth it.

For marine-grade cable that’s flexible, corrosion-resistant, and made right here in the U.S., procurement teams and boat owners turn to EWCS for their battery cable. Quality you can count on—voyage after voyage.

For more information about Electric Wire Cable and Quadruplex Wire Please visit: Electrical Wire & Cable Specialists.