In the ever-evolving manufacturing landscape, technology continues to push the boundaries of what is possible. One of the most transformative advancements in this field is the introduction and widespread adoption of robotic welding applications. This revolutionary technology, reshaping the way we think about manufacturing, is at the heart of what we do at Proteus IndustrialWe offer advanced solutions that improve precision, efficiency, and overall production quality, paving the way for a new era in manufacturing.

The Rise of Robotic Welding

Robotic welding applications have gained significant traction over the past few decades, revolutionizing the manufacturing industry. Compared to human welding techniques, these sophisticated technologies have many advantages, such as improved accuracy, speed, and safety. As manufacturers strive to remain competitive globally, integrating robotic welding technology has become essential.

Advantages of Robotic Welding Applications

- Enhanced Precision and Consistency

One of the key benefits of robotic welding applications is their ability to deliver consistent and precise welds. Modern robotic methods are designed to adhere to precise guidelines, which lowers the possibility of human error and guarantees consistency in each weld. For sectors like electronics, automotive, and aerospace that demand premium welds, this degree of accuracy is very advantageous.

- Increased Productivity

Robotic welding applications significantly boost productivity by performing welds faster than human welders. Robots can operate continuously without fatigue, ensuring consistent output and meeting tight production schedules. This increased efficiency allows manufacturers to take on larger projects and meet customer demands more effectively.

- Improved Safety

Welding can be hazardous, exposing workers to risks such as burns, eye damage, and inhalation of harmful fumes. By utilizing robotic welding applications, these risks are minimized as robots can operate in environments that may be dangerous for human workers. This reduces the risk of mishaps and injuries and makes the workplace safer.

- Cost Efficiency

While the initial investment in robotic welding applications can be large, the long-term cost savings are significant. Robots reduce the need for skilled labour, lower the incidence of rework due to errors, and minimize material waste. Over time, these savings can outweigh the initial costs, making robotic welding cost-effective.

- Flexibility and Versatility

Contemporary robotic welding applications are incredibly adaptable and simple to program to carry out a variety of welding jobs. This flexibility allows manufacturers to adapt to changing production needs and accommodate various welding applications. Whether it’s spot welding, arc welding, or laser welding, robotic systems can easily handle it all.

Key Applications of Robotic Welding in Manufacturing

- Automotive Industry

The automotive industry has been a pioneer in adopting robotic welding technology. Robots are used for spot welding car bodies, assembling components, and ensuring high-quality, consistent welds. This results in improved production efficiency and vehicle quality.

- Aerospace Industry

In the aerospace industry, precision and consistency are paramount. Robotic welding applications fabricate complex components, ensuring that each weld meets stringent quality standards. This enhances the safety and reliability of aircraft and spacecraft.

- Construction and Infrastructure

In the construction sector, robotic welding systems are being utilized more and more for jobs like welding pipelines, bridges, and structural steel. The ability to perform precise welds quickly and safely makes robots an ideal choice for large-scale infrastructure projects.

- Energy Sector

The renewable sector, including oil and gas, wind, and solar industries, relies on robotic welding applications for the fabrication and maintenance of various components. Robots provide consistent and high-quality welds, ensuring the integrity and longevity of energy infrastructure.

- Electronics Industry

The electronics industry requires precise and delicate welding for the assembly of small components. Robotic welding applications are ideal for this purpose, delivering accurate welds with minimal risk of damage to sensitive electronic parts.

Implementing Robotic Welding Applications with Proteus Industrial

At Proteus Industrial, we offer a comprehensive range of robotic welding applications designed to meet our clients’ specific needs. Our state-of-the-art technology ensures optimal performance and reliability, helping manufacturers achieve their production goals.

- Customized Solutions

We understand that each manufacturing operation is unique, which is why we provide tailored solutions to fulfil your particular requirements. Our staff of experts works directly with you to understand your production goals and design a robotic welding system that aligns with your needs.

- Advanced Technology

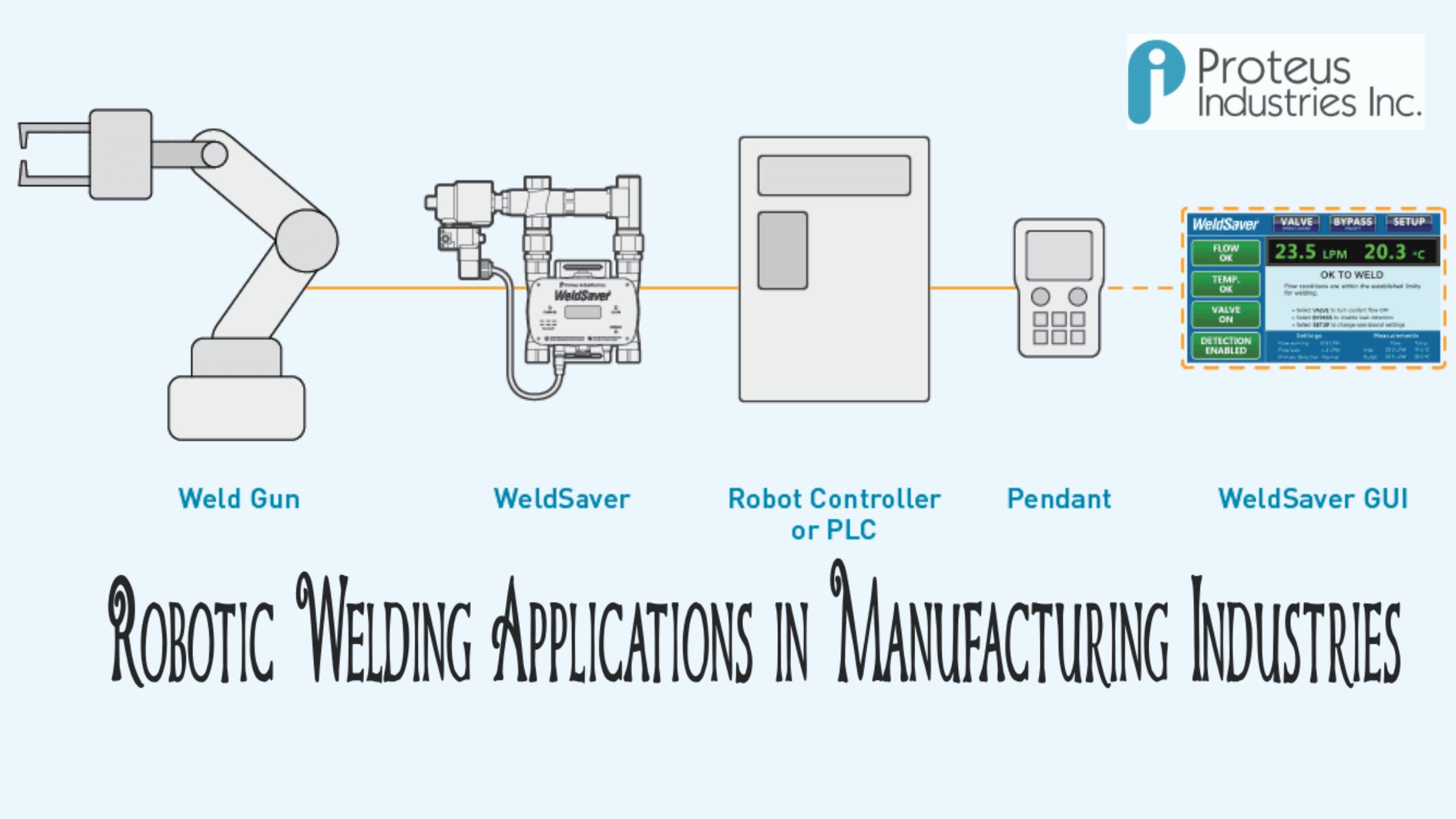

Our robotic welding applications incorporate the latest advancements in robotics and automation. From intuitive programming interfaces to real-time monitoring and control, our systems are equipped with features that enhance performance and productivity.

- Comprehensive Support and Training

Transitioning to robotic welding can be a significant change for any manufacturing operation. At Proteus Industrial, we offer comprehensive support and training to ensure a smooth implementation process. Our staff offers on-site training for your staff, making sure they are well-equipped to operate and maintain the robotic welding systems effectively.

- Maintenance and After-Sales Service

To guarantee the longevity and optimal performance of your robotic welding applications, we offer maintenance services and after-sales support. Our team can always assist with any technical issues, upgrades, or routine maintenance needs.

The Future of Robotic Welding Applications

As technology advances, robotic welding applications’ capabilities will only expand. Innovations such as artificial intelligence, machine learning, and the Internet of Things (IoT) are poised to further enhance robotic welding systems’ performance, flexibility, and efficiency. At Proteus Industrial, we are dedicated to staying at the forefront of these innovations and advancements, ensuring that our clients have access to the most cutting-edge solutions.

Conclusion

Robotic welding applications are transforming the manufacturing landscape by offering unparalleled precision, efficiency, and safety. At Proteus Industrial, we deliver top-of-the-line robotic welding systems that help our clients achieve their production goals. By investing in robotic welding applications, you can enhance your welding process, reduce costs, and improve the overall quality of your products.

Visit our website at Proteus Industrial for more information about our robotic welding applications and how they can benefit your operation. Our team is here to assist you in finding the ideal solution for your welding needs.